- Home

- »

- Quality Sealing Materials

- »

- Polyurethane

POLYURETHANE

ENGINEERING

Table of Contents

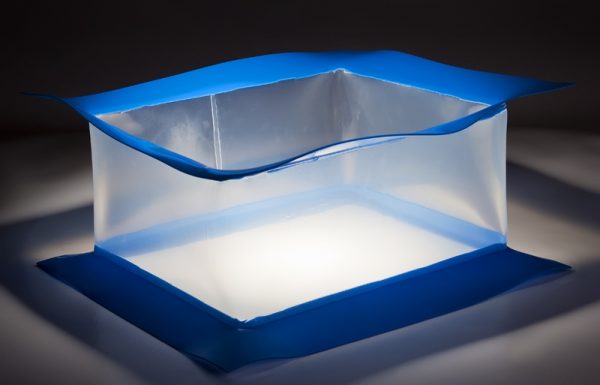

Strong. Tough. Durable. Versatile.

Polyurethane delivers important advantages over conventional elastomers and plastics – it is stronger, tougher, more durable, and more versatile. It’s better value than parts made with other materials, because they often crack, break, tear, swell, deteriorate, and abrade.

As a result, they can interrupt and slow down your business operation.

With customised cast or moulded urethane parts, you may never have to replace your parts again.

Tough, resilient materials; they can outperform steels and rubbers for abrasion resistance and can be moulded to any shape.

Microcellular pu’s have astonishing damping abilities, controlling shock, noise and vibration in the most arduous conditions.

We also offer both FDA compliant and metal detectable grades.

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your Pu requirements.

Pu Enquiry Form

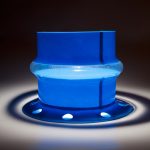

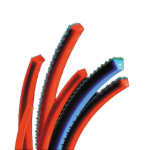

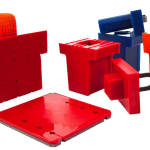

Pu Products we Supply

Click on the links below to download a data sheet on the different products.

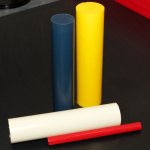

With a hardness range of 30° Sh A to 75° Sh D we offer a wide range of Polyurethane Rod from stock tooling in our full colour range. Usually 300mm long, rod can be supplied from 12mm diameter upwards.

As with all polymers it is recommended that the type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.