This guide has been written to help you measure a gasket.

A gasket can be any shape, and will always be designed to reflect the shape of the flange or style of the part that it needs to seal.

Below we will talk about the most common shapes of gaskets and offer advice, so you know how to measure them.

We will discuss some of the acronyms that you may encounter when using gasket terminology. These will be highlighted in bold for easy reference.

If you require additional advice in measuring for a gasket, please contact one of our experienced team. Alternatively you can always send us a sample that we will convert to a CAD file.

Main shapes of gaskets

Round Flange Gaskets

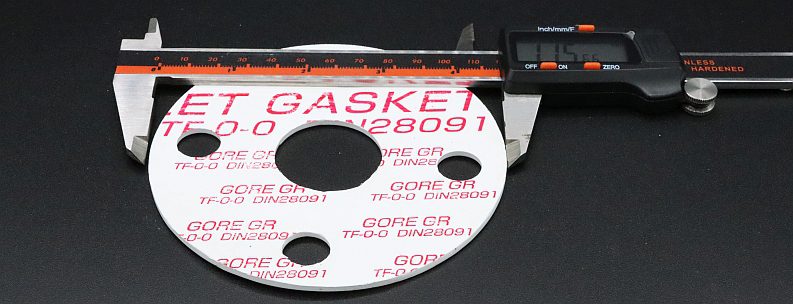

Round flange gaskets are the most common styles and are used in a wide variety of settings such as for sealing pipe flanges, washers in taps or as sealing rings in hoses.

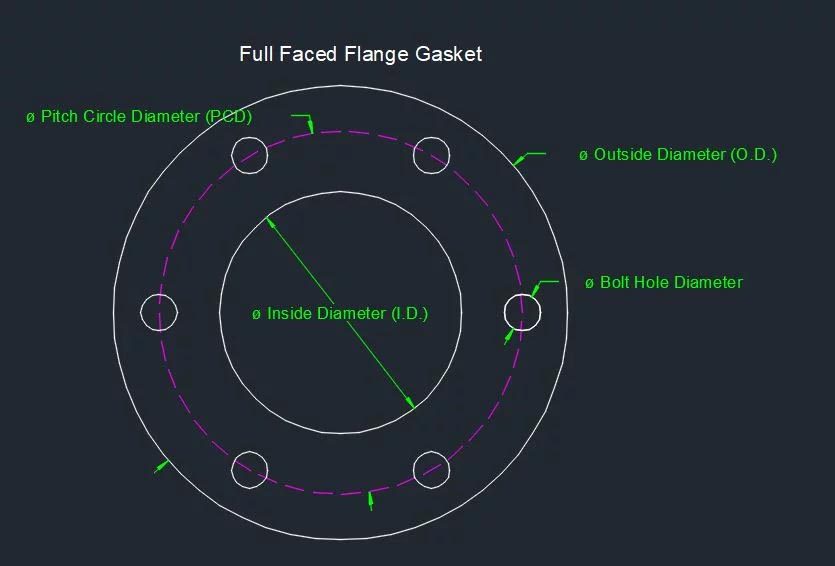

The two main types of round flange gaskets are referred to as full faced, where the gasket has holes for the bolts to go through to clamp the two flanges together.

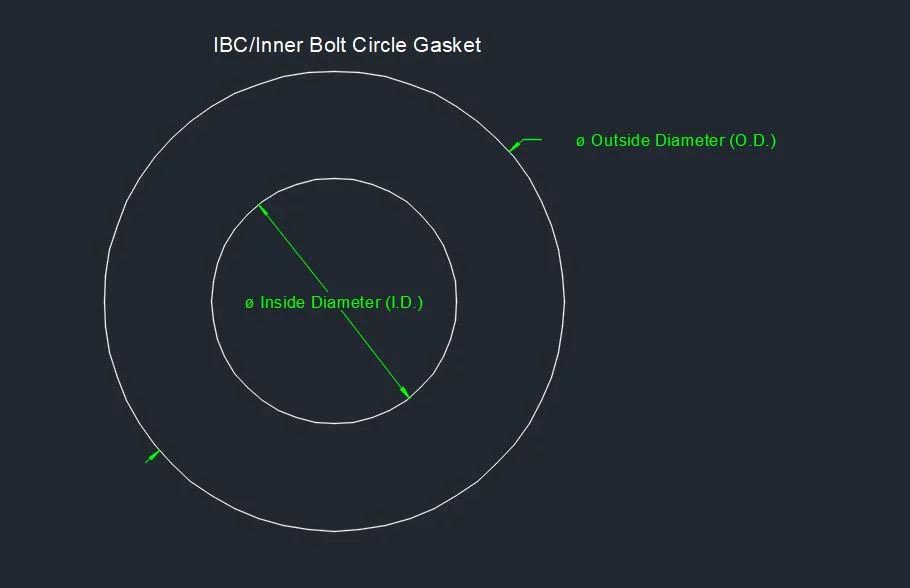

The other main style is called IBC, or Inner Bolt Circle, where, as the name suggests, these styles don’t have any holes for the bolts as they sit inside the bolt circle. These are often referred to as RF (Raised Face) gaskets, or even washers.

There are recognised “Standard Tables” for some styles of pipeline. See the links at the bottom of the page for a list of sizes for these types of flanges.

Of course, there can be variants of these two styles, such as “Mickey Mouse” gaskets, Tabbed gaskets and gaskets with either offset bolt holes or even multiple sets of bolt holes, which are used most commonly with wider flanges.

Click on the images for a larger drawing.

To measure a full faced flange gasket you would measure the o.d. plus the i.d.then state the number of holes, their size and the PCD.

E.g. 200mm o.d. x 100mm i.d. complete with 6 x 12mm holes equidistantlyspaced on a 150mm PCD.

To measure an IBC, Inner Bolt Circle gasket you would measure the o.d. plus the i.d.

E.g. 200mm o.d. x 100mm i.d.

Picture Frame Gaskets

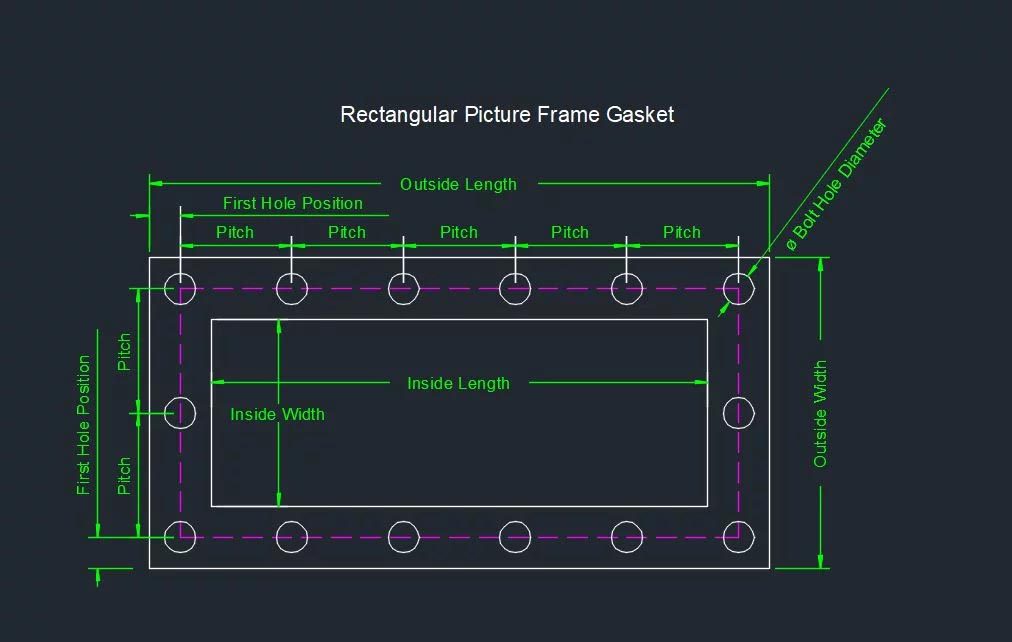

Picture frame gaskets are described as such because they resemble a picture.

They are generally rectangular or square and may or may not have radiused corners.

A tip here is that having a radius on the inside face strengthens the gasket as there is less chance of it tearing, particularly with more fragile materials like cork or paper.

These gaskets are designed to match the profile of the faces that need sealing. They are often used on ducting or as door seals.

There are variants of picture frame gaskets, including Ovals and Obrounds.

Click on the image for a larger drawing.

To measure a gasket that is rectangular or square, commonly referred to as a picture frame, you would measure the outside and inside lengths plus widths.

You would then measure the hole size, starting points and the pitch between holes.

An example may be, 400mm x 200mm outside, 300mm x 100mm inside, complete with 14 x 12mm holes starting 15mm in with a horizontal pitch of 74mm, and 85mm vertically.

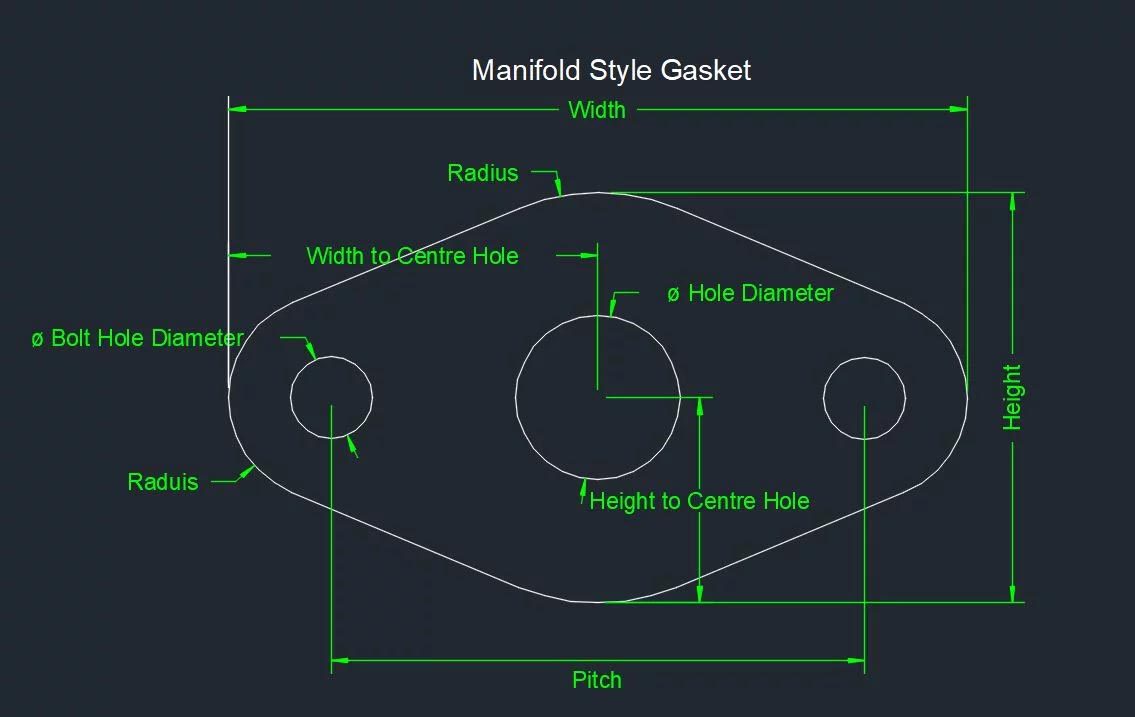

Manifold Automotive Gaskets

Manifold gaskets are used widely in the automotive sector for sealing flanges, particularly for exhausts.

They are also used in low pressure, low temperature applications within engines and are particularly suited to classic vehicle restoration.

Typical materials that would be used for manifold gaskets would be high temperature and mica based materials for exhausts and turbochargers. Many of these grades are suitable for use up to 1000º C.

Click on the image for a larger drawing.

To measure a manifold gasket you would measure the width and the height, then the position and size of the centre hole, finally the location, diameter and pitch between the bolt holes.

A tip here is that the radius can be worked out by taking a measurement from the middle of the centre hole to the top edge, and from the centre of the bolt holes to the outside edges.

What other information is required?

The following questions will assist us in quoting in the correct material for your application when you measure a gasket.

We stock over 100 different gasket materials, so you can be sure that we will have the right product for your application.

Glossary

| CAD File | A Computer Aided Design file used to produce a technical drawing for producing the gasket or seal. |

| Standard Tables | Published tables of gasket sizes for standard flanges. |

| Full Faced Gasket | A round gasket that has holes in it for the bolts on a flange to go through. |

| IBC Gasket | Inner Bolt Circle gasket, is a round gasket without bolt holes. |

| RF Gasket | Raised Face Gasket is the same as an IBC gasket. |

| “Mickey Mouse” Gasket | These are a cross between an IBC and a Full Faced gasket. The have just 2 bolt holes for locating the gasket. |

| Tabbed Gasket | Tabbed gaskets are similar to a “Mickey Mouse” gasket but with just one bolt hole, or they can be a blind tab without bolt holes, designed for ease of fitting. |

| O.D. | Outside diameter of the gasket. |

| I.D. | Inside diameter of the gasket. |

| Equidistantly | Meaning that the holes have an equal distance between them on the PCD. If the holes aren’t equidistantly spaced, we would need the angles to the holes. |

| P.C.D. | Pitch Circle Diameter. This defines where the bolt holes are. |

| Picture frame | Describes in general a square or rectangular gasket, with or without holes, that resembles a picture frame. |

| Oval | Describes an elliptical gasket. These can be quite complicated to measure as they have X and Y axis. |

| Obround | A phrase to describe two semi-circles joined by parallel lines, a cross between a rectangular picture frame and an Oval. |

| Pitch | The distance between holes. |

| Manifold Gaskets | Used to describe the shape of gasket. The may not necessarily go on a manifold. |

| Mica | A silicate mineral used for high temperature gaskets used in exhausts and turbo-chargers. |

| FDA | US Food and Drugs Administration. CFR21 FDA 177-2600 is a list that states permitted ingredients in materials for use in food applications. |

| EC1935:2004 | Is the European directive governing materials used within the food industry. |

Standard Gasket Tables

| Gasket Standard | More information |

|---|---|

| BS10:2009 | BS10 Tables A, D, E, F, H, J, K and R. Replaces BS10:1962 |

| BS EN 12560-1:2001 | Aligned with the American ASME B16.21 standard, covering classes ASA150, 300, 400, 600 & 900. |

| ASME B16.47 Series A | Large Diameter gaskets in classes 150, 300, 400, 600 & 900. Previously MSS SP-44. |

| ASME B16.47 Series B | Large Diameter gaskets in classes 75, 150, 300, 400, 600 & 900. Previously API605. |

| BS EN 1514-1:2004 | Dimensions of gaskets for PN designated flanges. Covering Tables PN2.5, 6, 10, 16, 25, 40 & 63. |

| JIS | Japanese Industrial Flanges. Tables 5K, 10K, 16K & 20K |

| Taylor Forge | First published in 1938, bulletin 502 laid down the Taylor Forge principles for flange design. Sizes are outlined here for classes 75, 125, 175, 250 and 350. |