RUBBER EXTRUSIONS

& CORD

RUBBER EXTRUSIONS

& CORD

Extrusions

For some applications, rubber extrusions may be the answer when a fully moulded rubber part is not a viable option due to the cost involved, size required, and even something as simple as fitting constraints. For this type of part, our rubber extrusions could be the answer. It can be supplied as either a finished part, a full length to be cut and fitted on site, or even vulcanise joined into an endless length.

Whether you need a standard square section or a bespoke lip profile we manufacture rapidly and accurately in our wide range of elastomeric polymers and hardness’s to suit your application. Some compounds are available with WRAS approval or FDA/EC1935:2004 compliance.

All of our Rubber Extrusions are manufactured to RMA Class E1 or Class E2 tolerances.

What is rubber extrusion?

Rubber extrusions are a versatile product, used in a variety of applications, from weatherproofing to noise reduction. Different types of extrusions are available on the market, made from rubbers such as silicone and natural rubber, each with its unique set of properties.

How are rubber extrusions made?

Extrusion is a process where the rubber is forced through a die of the desired cross-sectional shape. The raw rubber material, or “biscuit”, is first softened by heat and then fed into the extruder. The extruder consists of a screw that turns within a heated barrel. As the screw turns, it melts the biscuit and forces it through the die. The cross-sectional die determines the final form of the extruded rubber profiles.

What are the different types of rubber extrusions?

There are two main types of extrusions made from rubber are solid and sponge. Solid extrusions are dense and have a smooth surface. Sponge extrusions are less dense and have a porous, spongy surface.

Sponge extrusions are often used in applications where they will be subject to compressions, such as door and window seals. Solid extrusions are often used in applications where resistance to wear and tear is important, such as automotive weather-stripping.

What is an extruded seal?

An extruded seal is a type of rubber seal that is made by forcing raw rubber material through a die of the desired form. This process can be used to create seals of various shapes and sizes and is popular for its versatility and affordability.

What are the benefits of rubber extrusions?

There are many benefits to using extrusions, including:

– They can be custom-made to nearly any size and shape,

– They’re weather resistant and durable,

– They have a wide range of applications,

-They have noise control qualities,

-They have vibration dampening qualities,

Extruded rubber products are an excellent choice for a range of applications requiring weather resistance, durability, and a custom fit.

What are rubber extrusions used for?

– Automotive -and Marine for panel sealing, gasket seals, and as a bonnet seal.

– Industrial, Manufacture, and Electrical

– for dust exclusion, as rubber gaskets, for gap filling and weather exclusion purposes.

– Construction for sliding doors, and sliding windows and generally as glazing seals.

Rubber seals and door seals

Rubber extrusions are also ideal for use indoors, as they help to keep out drafts, dust, and water, and can also provide insulation. There are many different types of door seals available on the market including PVC ones, Neoprene ones, EPDM ones, and silicone ones.

The different types of rubber extrusion are designed for specific applications. For example, weatherproofing rubber is typically made from a harder type of rubber, such as EPDM, which can withstand extreme temperatures and UV exposure. Softer rubbers, such as neoprene, are often used as seals for doors and other similar applications where a softer, more pliable material is required.

Can EPDM be extruded?

EPDM rubber can be extruded, but it is not the best material for the process. EPDM rubber is designed for injection moulding, not extrusion. As a result, it does not flow well and can cause problems with the extrusion process. Additionally, EPDM rubber is not as durable as other types of rubber and may not withstand the wear and tear of an extrusion process.

If you need a rubber extrusion, it is best to choose a material that is specifically designed for extrusion, such as nitrile rubber (NBR). Nitrile rubber is a synthetic rubber that is designed for extrusion and has superior resistance to wear and tear.

Cord

Our cord range is extensive. We stock a range of Neoprene sponge and solid cords from 3mm – 25mm diameter. They can be supplied either in open lengths or joined to form O-Rings.

For high temperature applications, both Viton and Silicone cords are stocked.

If your requirement is for bespoke sizes from our huge range of polymers these are available subject to minimum order quantities to RMA Class E1 tolerances.

Choose Munsch & Co/PTM Ltd. for all your rubber extrusion needs.

There are many companies on the market that supply rubber extrusions, but only our company has an extensive catalogue, where you will find we supply a comprehensive range of rubber products we manufacture from a vast array of materials including standard rubber extrusions and those made of natural rubber.

All you need to do is fill in the information below and one of our experts will give you all the advice and guidance you need on our Products Rubber Extrusions.

OTHER PRODUCTS

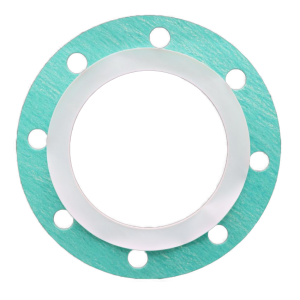

Gaskets

Munsch and Co/PTM are a prominent supplier and manufacturer of gaskets, which are used widely in industries throughout the UK, Europe and worldwide. We make gaskets in numerous materials, from rubber and sponge, for low pressure to metallic and semi-metallic for high pressure, high temperature applications.

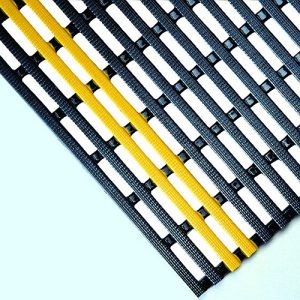

Matting

We strive to help keep people safe and comfortable in many environments through specifying, supplying & delivering quality matting and flooring solutions. Keeping abreast of legislation changes means we offer the latest range of safety mats, particularly electrical to the latest standard, BS EN 61111:2009.

Hose & Ducting

Our comprehensive range of hose and ducting is used extensively in industries throughout the country and the continent, and can be complimented with a wide range of high quality fittings. Using only high quality UK and European manufacturers, our hose and ducting and tubing range is second to none.

Pump Packing

Compression packing/s, or pump & gland seals are used under a range of conditions to seal a variety of fluids. They are used to contain water, acids, solvents, gases, oil, and other chemicals that are subjected to various temps. and pressures and are commonly used on valves, pumps and other rotary and reciprocating equipment.

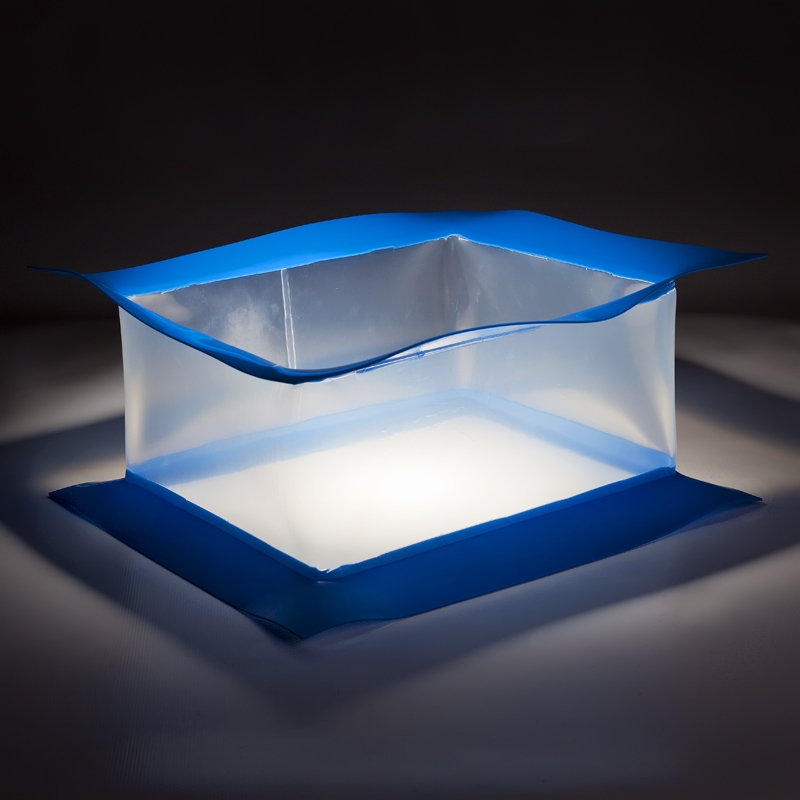

Inflatable Seals

Iso-Flate™ inflatable seals are manufactured in the UK and are designed to provide efficient hermetic sealing solutions providing protection against incursions by powders, granules, gases, liquids and dust. These pneumatic airtight seals are extremely useful for sealing fabricated pieces of equipment.

Mouldings

Munsch & Co/PTM can supply the shape, style and quantity that you require if your process requires a rubber moulding. Available from our full range of elastomeric polymers. Our compounds are available in varying hardness’s. From as low as 20° shore A, up to 95° shore A. Plus, if you require a specific colour for your seal, please ask.

Fabrications

With over 45 years experience hand fabricating our complete range of materials including rubber, sponge, textiles and welded polyurethane we are able to offer solutions to even the most diverse problems. Whether the requirement is for a simple sleeve or a more complex chute liner we have the expertise and skill to make it.

Rollers & Wheel Covering

Rubber rollers & Polyurethane covered rollers and wheels are found in a broad range of industries including textiles, paper and board, food, packaging, aggregates, engineering, manufacturing, and pharmaceutical etc. We offer a full grinding, cambering and grooving service.

Extrusions & Cord

For some applications, a fully moulded rubber part is not a viable option due to the cost involved, size required, and even something as simple as fitting constraints. For this type of part, our range of extrusions could be the answer. Whether it be a custom designed profile or an "off the shelf" square section or cord, we can help.

Strips, Scrapers & Skirts

Rubber, sponge, Polyurethane, foam, belting and felt strips are a large part of our business. We supply thousands of metres of strip per month. Whether you require the strip plain or self adhesive backed* we can supply it. Our in-house machinery includes 5 strip machines, guillotines, and log cutters.

O-Rings and Bonded Seals

With our massive stocks of O-rings in Nitrile, Viton and PTFE, you can be assured of quick delivery, when you need it. The ‘O’ Ring is a simple, versatile, economical but essential component with a vast range of uses. We also carry substantial stocks of Dowty (Bonded) seals.

Metal-Detectable Range

Metal detectable materials are increasing in popularity and are now commonplace in food, beverage and pharmaceutical industries, because, in the event of a gasket or seal failing, any fragments of material can be picked up by metal detectors so they don’t contaminate the product.

PVC Curtains & Crash Doors

One of the most economical and efficient solutions to retain warmth or cold, and to prevent entry by birds and insects, while still allowing safe passage for pedestrians and fork lift trucks, PVC Strip Curtains are often the preferred choice for warehouses, shops, cold stores and factories.

Impact Protection

Made from flexible age resistant polyurethane foam, our Impact Protection profiles provide both visual warning and safety cushioning to hard, unyielding objects. They prevent injury and protect property are quick and easy to install and can be easily cut to length with sharp knife, scissors or a fine saw blade.

Hose Fittings & Assemblies

To complement our vast hose range, we stock and supply a wide range of hose fittings, clamps and assemblies.

We can provide Hydrostatic Pressure Testing and Certification, along with electrical continuity testing as appropriate.