We manufacture PTFE Gaskets from our complete range of Polytetrafluoroethlyene (PTFE) materials. Commonly referred to as Teflon (The well known brand name of The Chemours Company), PTFE has outstanding resistance to chemicals, a wide temperature range, withstanding (–200° C to +260° C) and excellent dielectric properties.

Being chemically inert, except for some alkaline metals, means PTFE Gaskets are the seals of choice in food, pharmaceutical and chemical sectors.

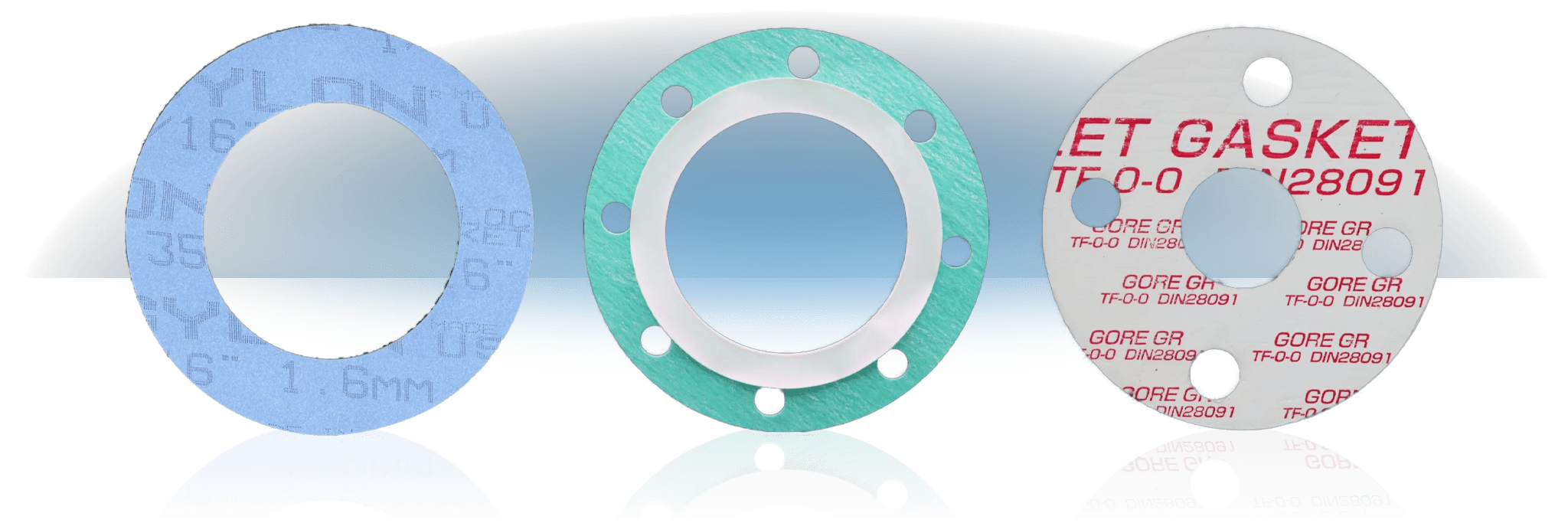

PTFE can be divided into two main styles. Virgin PTFE, which is fairly hard, like plastic, however it will still compress to make a seal between two faces. Expanded PTFE is more like a sponge, making it ideal for sealing damaged, glass or plastic flanges because it compresses more easily than the Virgin grade.

As one of the largest gasket cutters in the United Kingdom, we make and supply PTFE gaskets in a broad range of different variants including, etched and filled grades.

We also manufacture PTFE Envelope gaskets in-house. The PTFE Envelope is fitted on the inside diameter (bore) of the gasket. The gaskets are usually made from non-asbestos fibre or rubber. The advantage of this style of gasket is that it combines the inertness of PTFE with the mechanical properties of the outer gasket. Above all, because the envelope only covers the bore, it saves you the expense of a complete PTFE gasket.

Main Benefits of PTFE

- Low coefficient of friction

- Excellent chemical inertness

- Non-adhesive surface

- Wide temperature range withstanding (–200° C to +260° C)

- Excellent dielectric properties

- Filled grades available

- Can be supplied etched, if bonding is required

- Most grades are both FDA/EC1935:2004 and WRAS Compliant

Grades of PTFE that we manufacture Gaskets from

Click on the links below to download a data sheet on the different grades.

Virgin PTFE

Expanded PTFE

Etched PTFE

25% Glass Filled PTFE

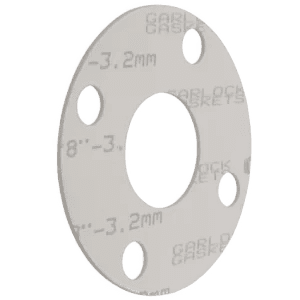

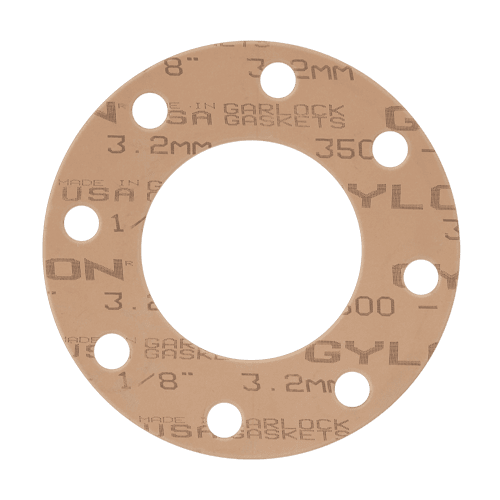

Garlock PTFE Styles

As an authorised Garlock distributor we carry the complete Gylon® range to be converted into gylon gaskets. Visit our dedicated Gylon® page, or see below for links to data sheets on each style.

Gylon® BIO-LINE®

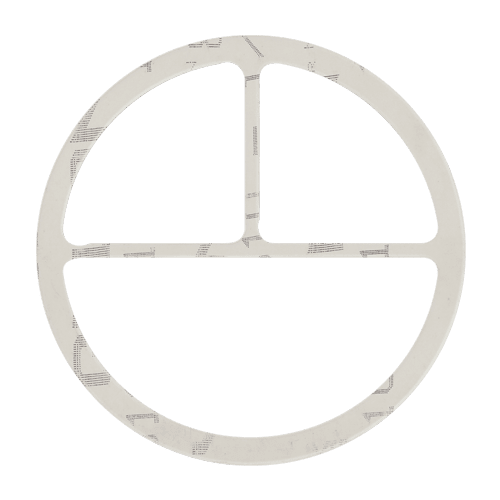

Gylon® 3565 Envelon

Gylon® 3545

Gylon® 3540

Gylon® 3510

Gylon® 3504

Gylon® 3501

Gylon® 3500

Flexitallic PTFE Grades

Sigma® 588

Sigma® 533

Sigma® 511

Sigma® 500

Klinger & Gore PTFE Gaskets

Top-Chem 2006

Top-Chem 2005

Top-Chem 2003

Top-Chem 2000

As with all types of gaskets, it is recommended that the material type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.