GASKETS

WE MANUFACTURE AND SUPPLY

GASKETS

WE MANUFACTURE AND SUPPLY

Table of Contents

Munsch and Co/PTM are a prominent supplier and manufacturer of gaskets, which are used widely in industries throughout the UK, Europe and worldwide.

What is a gasket?

A gasket is made from a compressible material that is used to create a seal between two stationary faces such as pipe flanges.

Why will I need a gasket?

You will need a gasket to create a seal, as it is extremely difficult to achieve completely smooth faces on metalwork. Also, potential erosion and corrosion of the faces over time could cause the joint to fail without a gasket.

How does the gasket work?

To be effective a gasket must be subject to sufficient force when being seated for it to compress and make the seal. Sufficient pressure must be applied and maintained once seated, to retain the seal.

Do I need to know anything else?

Yes, it is important that the chosen material for the gasket is suitable for the media it is coming into contact with, and that it can handle the temperature and pressure.

We have been manufacturing gaskets for over 50 years, in a wide range of materials, from EPDM for water applications, to Gylon® for the pharmaceutical and chemical industries.

Working together with you to find the most suitable solution from our wide range of materials, means you will get the correct product for the application. Sometimes cost is the overriding concern, but more often than not, it’s the longevity of the seal, which is why we only supply gaskets manufactured from quality materials.

With over 100 years combined experience, our team are knowledgeable in all styles of gaskets, which means we can analyse, advise, and recommend a solution to even the most complicated gasketing problem.

Manufacturing

Our manufacturing capabilities are extensive in our 11,000 square foot gasket shop. We have 10 presses available ranging from 20 to 80 tonnes, and with over 15,000 cutting formes to choose from, many standard sizes and styles are available without incurring tooling costs, which can save you money.

For bespoke designs we now utilise our 2 axis CNC cutters. These allow us to produce complex designs in a variety of materials without the need for, sometimes expensive tooling; plus with the cut being done with a knife there are no laser scorch marks.

For thicker gauges, we cut using a 55000 psi water jet cutter. This allows us to cut up to 100mm thick materials, without edge deformation, plus with the jet being only 1mm diameter there is very little wastage between cuts, meaning it saves you money.

For large gaskets (Bigger than either roll or sheet size) we can supply them in pieces with dovetail joints pre-cut.

You can e-mail your designs to us or we can input them directly from your drawings.

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your gasketing requirements.

Gaskets Enquiry

Types of Gaskets we supply

Types of Gaskets we supply

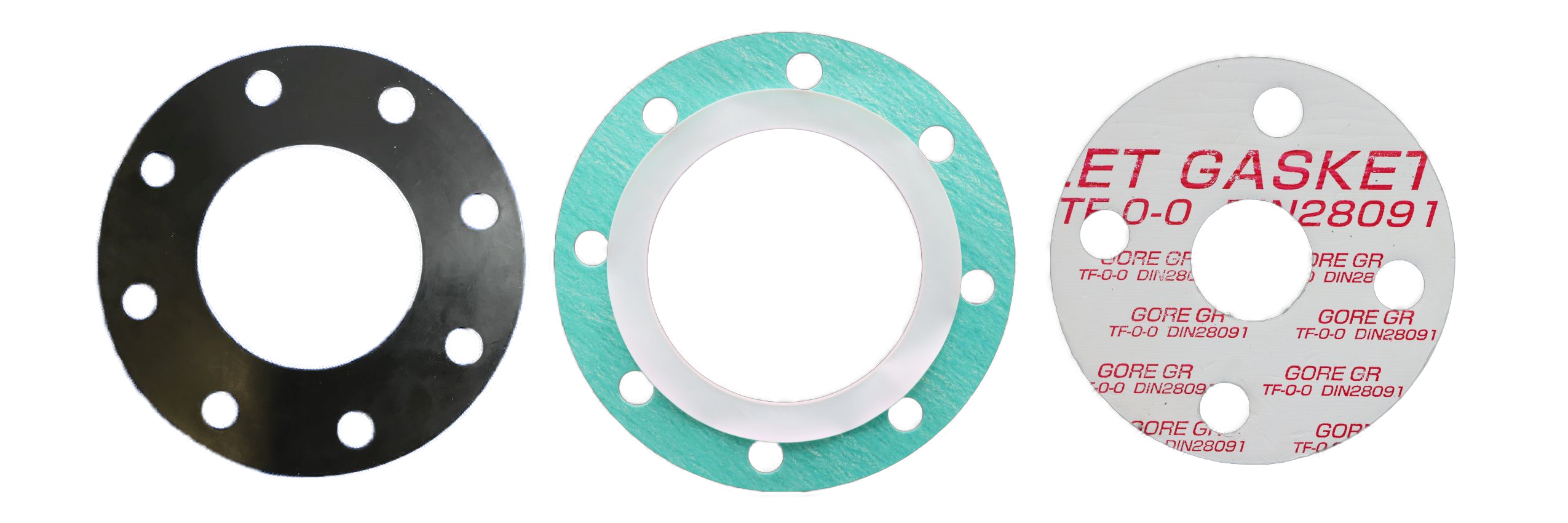

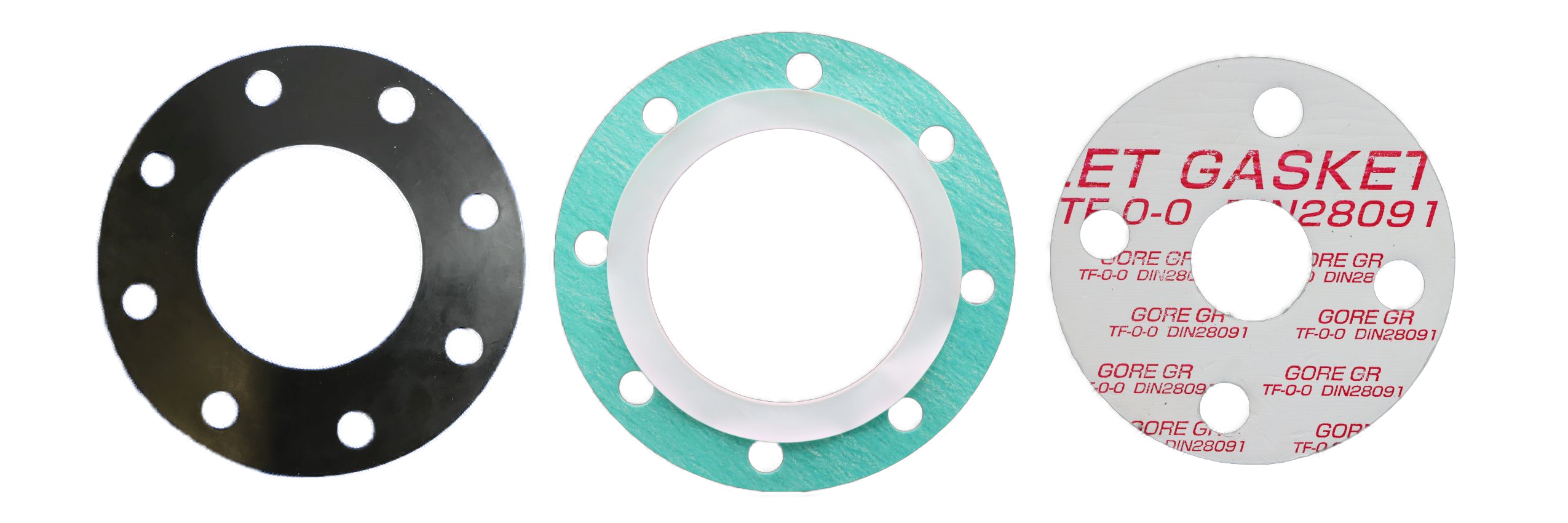

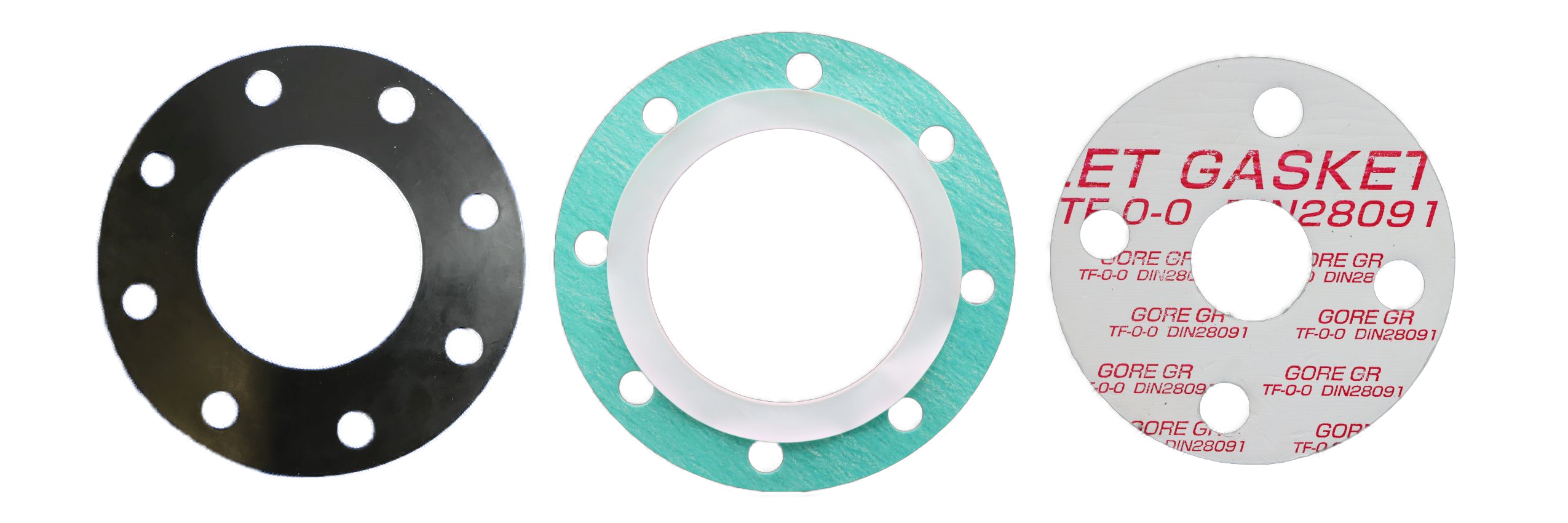

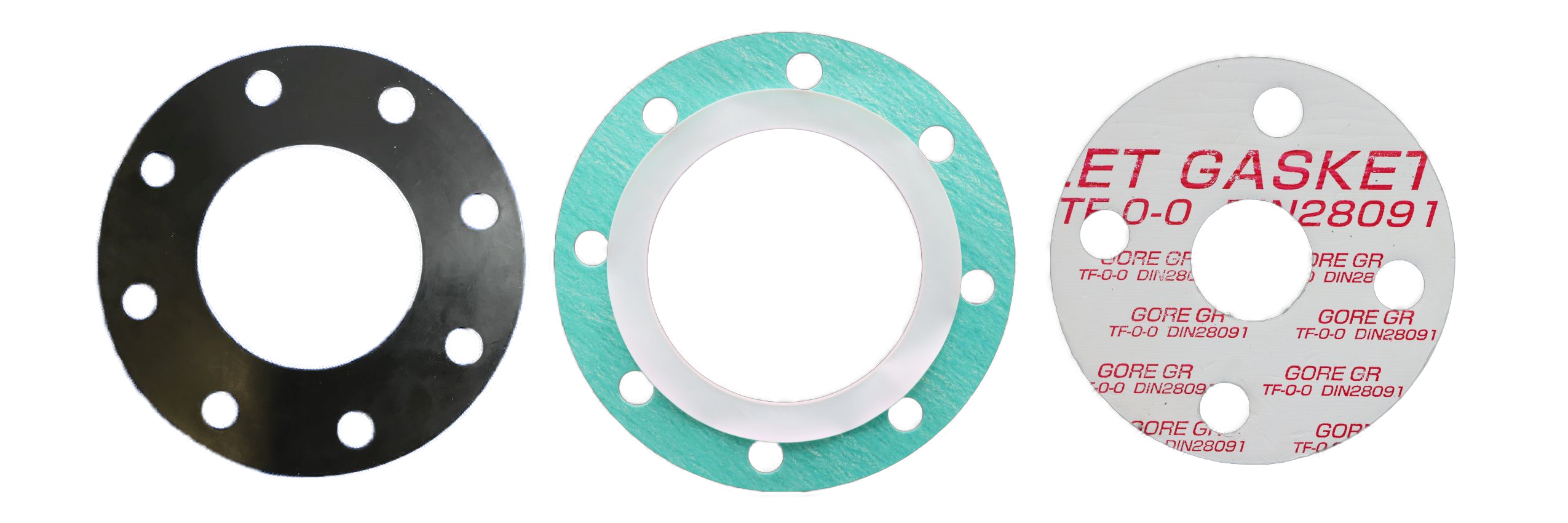

Below, we will explain about the different materials that we supply and manufacture gaskets from, and applications that they are most suited to.

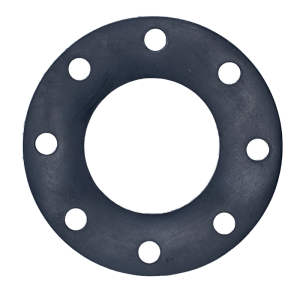

Rubber

Designed for low pressure sealing applications. Rubber seals compress easily and can be used with a wide range of liquids and gases.

Depending on polymer style, rubber has a wide temperature range of between -70° and + 250° C.

We carry a wide selection of polymers from 0.75mm to 50mm thick, including FDA/EC1935 grades, WRAS approved, for drinking water, metal detectable and BS Standards.

Compressed Non-Asbestos Fibre

Compressed Non-Asbestos fibre (CNAF/NAF) is used for high temperature (Up to + 400° C) and/or high pressure (Up to 140 BAR). Suitable for use with a wide range of medias including oil, fuel, acids, steam and gases.

CNAF is a blend of aramid or inorganic fibres together with a rubber binder, which has been widely used since the ban on asbestos in 1999.

Our range of material is extensive, and we supply material from the worlds leading manufacturers.

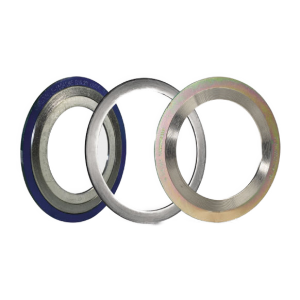

Metallic & Semi-Metallic

Designed to withstand extreme pressures (Up to 400 BAR), and high temperatures (Up to + 1000° C), and having excellent chemical resistance, our range of metallic seals is comprehensive.

Our styles of metallic gaskets include Spiral Wound, RTJ’s (Ring Type Joints), Heat Exchanger Gaskets, Machined metal, clad, heat exchanger and tinplate.

Sponge

If a very low pressure seal is required, our range of sponge may provide the solution. Similar to rubber, the temperature range of sponge, dependent on the grade, ranges from -60° to + 200° C.

We supply two main styles of sponge, Open-Cell and Closed-Cell.

The polymer types include Neoprene, EPDM, Silicone, Viton and PVC Nitrile and can be supplied plain or self-adhesive backed.

PTFE

Polytetrafluoroethylene has outstanding chemical resistance and a broad temperature range of -200° to + 260° C.

As the material is chemically inert, it is often the preferred choice for gaskets within the food, pharmaceutical, and chemical sectors.

We offer all styles of PTFE including, virgin, expanded, filled and etched so you can be assured of the right product.

Cork

Our range of cork materials includes Nitrile and Neoprene bonded corks as well as Nebar®, Tico® and BS grades.

Rubber bonded cork is used in controlled swell environments, particularly for sump gaskets and also for switchgear housings.

Cork provides excellent dampening characteristics making it ideal for a wide range of sealing applications.

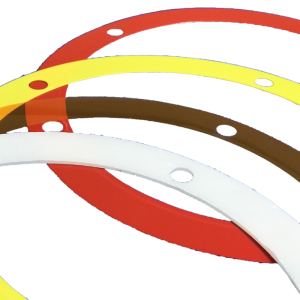

Plastic

We carry a complete range of engineering plastics and offer a full cutting service.

The most common style is our comprehensive range of colour coded plastic shimstock, which means you can easily identify the thickness.

Manufactured from polypropylene or polyester, depending on thickness, we supply full shim sets made from a combination of thicknesses.

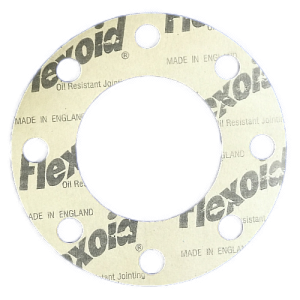

Paper

Our range of coated papers are used primarily within the automotive industry.

Price sensitive materials are an important requirement within this sector, and our range of oil and fuel resistant grades are ideal for sealing in low heat applications.

Our range of Statite™ and Flexoid™ papers are stocked from 0.15mm to 3mm ensuring you get quick delivery.

High Temperature

Our range of graphite and mica based materials are used for sealing at extremely high temperatures.

Dependent on the grade, this range is suitable for use up to 1000°C.

Commonly used within the automotive, oil and gas, and power industries, our range is produced in accordance with ISO9001:2015 to ensure you get consistent quality.

More Information

How to measure a gasket

For advice on how to measure a gasket, please see our handy technical bulletin.

It covers round, square, rectangular and manifold styles.

Simply click here, or the image on the right.