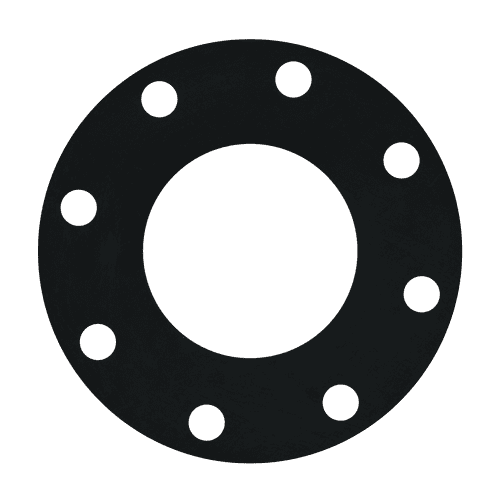

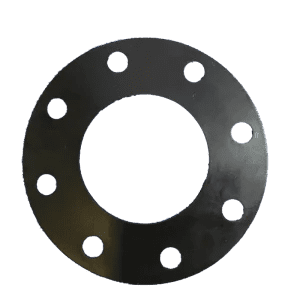

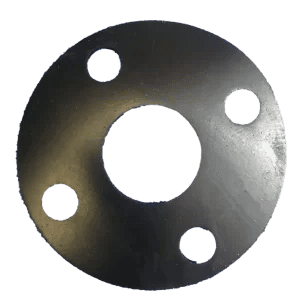

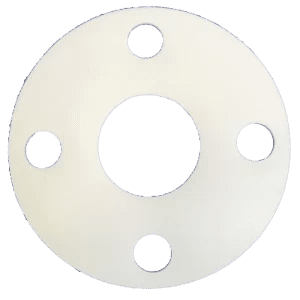

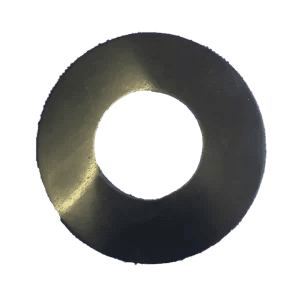

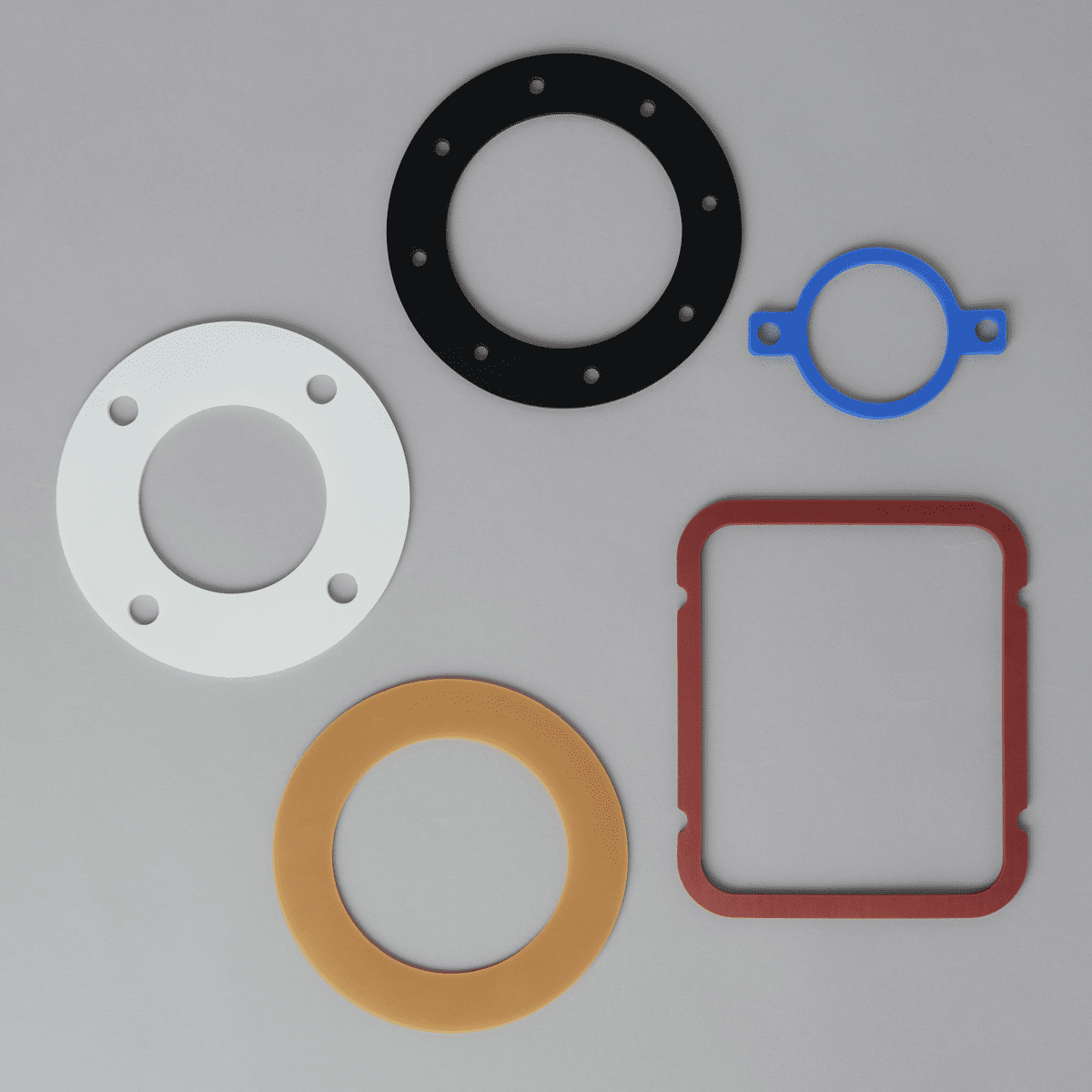

Rubber gaskets are built to compress under pressure, forming a tight seal between two surfaces to prevent leaks, keep out dust, or maintain airtight or watertight connections. They’re commonly used across a wide range of industries, including automotive, aerospace, construction, and manufacturing, because they provide a reliable barrier against fluids, gases, and other unwanted elements. Whether it’s a small engine component or a large industrial system, a properly fitted rubber gasket ensures dependable performance and reduces the risk of failure or damage.

We supply and manufacture all kinds of rubber gaskets and seals for customers across the UK and overseas. Our product range includes standard and custom sizes made from a variety of rubber materials, tailored to suit different pressure, temperature, and chemical resistance requirements. Thanks to our unique pricing system, where we remove the cost of the centre material during production, you benefit from significant cost savings. This centring-out approach means you only pay for the rubber you actually need, making our rubber gaskets not just reliable but also more economical.

Well known across the sealing industry, our team brings together over 100 years of hands-on experience in delivering reliable sealing solutions. If you need rubber gaskets outside the standard range, we’ll work closely with you to develop a custom seal that fits your specific needs. This includes advising on the most suitable polymer, the design of the gasket, and the best production method to use.

With over 15,000 cutting formes in stock and two advanced CAD/CAM oscillating knife cutting tables, we’re fully equipped to provide fast turnaround times and dependable delivery.

The quality of rubber gaskets can vary greatly depending on the grade of material used. That’s why we only source rubber from trusted, high-quality suppliers. This ensures every gasket we produce meets a consistent, reliable standard.

Below, we break down the range of polymers we offer and explain their typical uses. Different rubber types offer different levels of chemical resistance and perform differently under heat, so choosing the right one matters.

Types of Rubber Gaskets

Click on the links below to download a data sheet on the different grades.

EPDM & Butyl

WRAS Approved EPDM

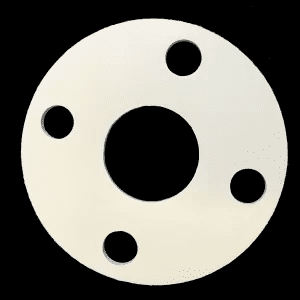

White Food Quality EPDM Gaskets

EPDM (Commercial)

Butyl Gaskets

Hypalon & Natural

White Food Quality Natural

Tan Para/Natural Rubber

Natural Rubber/SBR Gaskets

Natural Rubber/SBR c/w Insertion Gaskets

Natural Rubber BS1154

CSM/Hypalon™ Gaskets

Acrylonitrile Butadiene/Nitrile

Semperit P559 Nitrile

Nitrile Gaskets

FDA White Nitrile

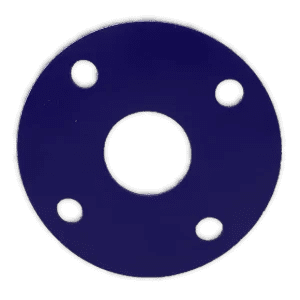

FDA Blue Metal Detectable Nitrile

BS2751 Nitrile Gaskets

Blue Food Quality Nitrile Gaskets

Polychloroprene/Neoprene

White Food Quality Neoprene Gaskets

Flame Retardant Neoprene – NCB158

Chloroprene /Neoprene Gaskets

BS2752 Neoprene Gaskets

Silicone

Platinum Cured Silicone Gaskets

Blue Metal Detectable Silicone

60° Sh A Silicone

40° Sh A Silicone Seals

Viton and FKM

Viton A™ Gaskets

Nomex Re-inforced FKM Gaskets

FKM Gaskets

Beige/Blue FKM

As with all types of rubber, it is recommended that the polymer type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.

Viton A™ is a trademark of The Chemours Company