Iso-Flate™ inflatable seals are manufactured in the UK and are designed to provide efficient hermetic sealing solutions providing protection against incursions by powders, granules, gases, liquids and dust.

These pneumatic airtight seals are extremely useful for sealing fabricated pieces of equipment where:

- The sealing gap might vary

- Assembly and dis-assembly needs to be quick and simple

- Hygienic procedures exist (FDA applications and regulations)

- Generally working from within a specific groove size the seals can operate axially, and for both inward and outward radial movements.

The most popular requirements are for FDA approved Silicone elastomers in either blue, white or red iron oxide colours. Other elastomers and pigmentation’s are available for a wide variety of sealing applications.

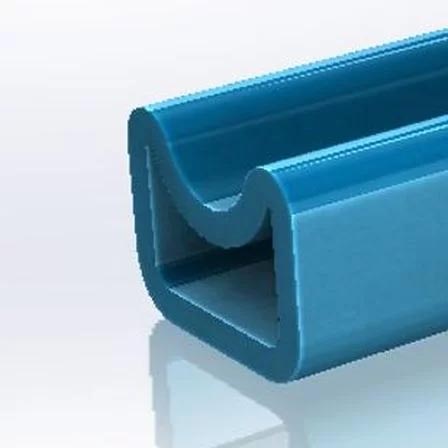

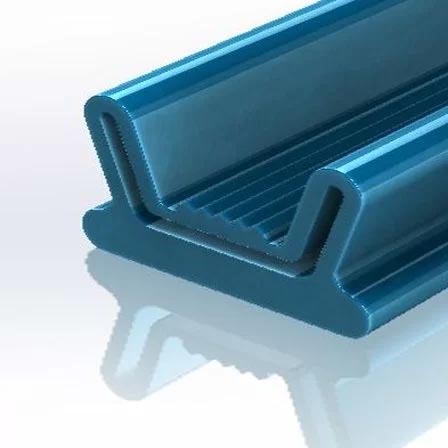

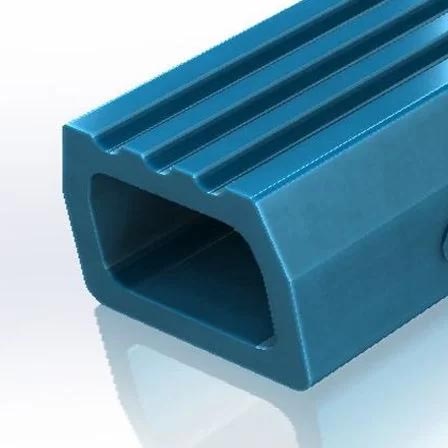

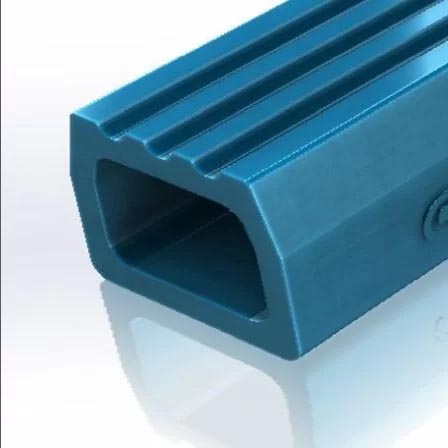

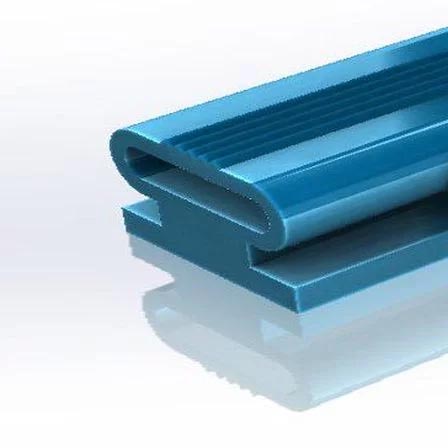

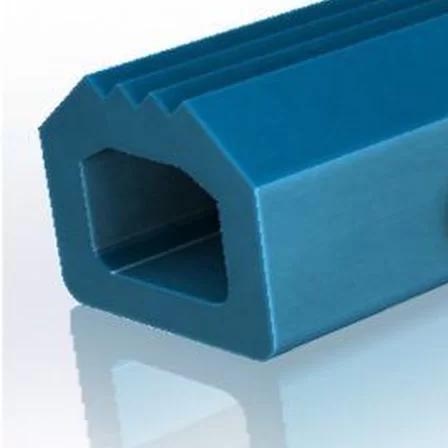

Stock Profiles

We carry a large number of “common profiles” on stock, this enables us to provide a very quick turnaround of inflatable seals when required. Our pneumatic seal joining method incorporates a high pressure shot moulding technique (vulcanising), this utilises an identical compound injected at the joint to produce a high strength bond, resulting in a clean smooth line finish. No adhesives form part of the bond. This process provides a high integrity seal capable of performing under greater and higher pressures than most if not all other similar type of seals in the market.

A ‘shot moulding’ technique is also used to bond most types of the available inflation connectors to the seals as required by the customer/application. This process bonds the connector to the seal by localised injection of identical compound vulcanising the connector to the seal. The strength of vulcanised connector far exceeds any mechanical fixing or adhesive bonded connector, associated with this type of seal.

Other materials are also available which include Fluoro-polymers such as Viton® and Fluorosilicone, Anti-Bacterial Silver loaded Silicones and EPDM.

Inflatable Seals for Marine Applications

The ISO-FLATE™ range of inflatable seals are an ideal Guarantees / Accreditations solution for reliable weather tight and UV/ saltwater resistant sealing. Our team has all the experience, and latest 3D modelling technology available to work with you from the outset, and develop a high end solution using existing or bespoke profiles.

We can produce an incredible number of different designs, using our wide range of profiles and tooling (including 90° corner seals for axial inflation).

Product Features

- Precision spark eroded vulcanisation tooling, and strict extrusion tolerance ensures highest quality of vulcanisation

- Over 100 profiles available in FDA silicone, Anti-Microbial Silicone, FDA EPDM, FKM and many other materials

- Precision moulded rubber valves, and machined steel valves to suit vast range of housings adhering to stringent leak rates

- Unique seal identification number providing detailed traceability for each individual seal supplied

- Rapid cycle fatigue testing available providing accurate, application specific cycle life estimates

- High quality of vulcanisation in almost any RAL number for aesthetically stunning seal/door combinations

Typical Marine Uses

- Transom Hatches

- Patio Doors

- Tender Doors

- Forward Hatch Seals For Racing

- Sun Decks

- Composite Moulding

- Vacuum Forming

See below for the most common profiles we supply.