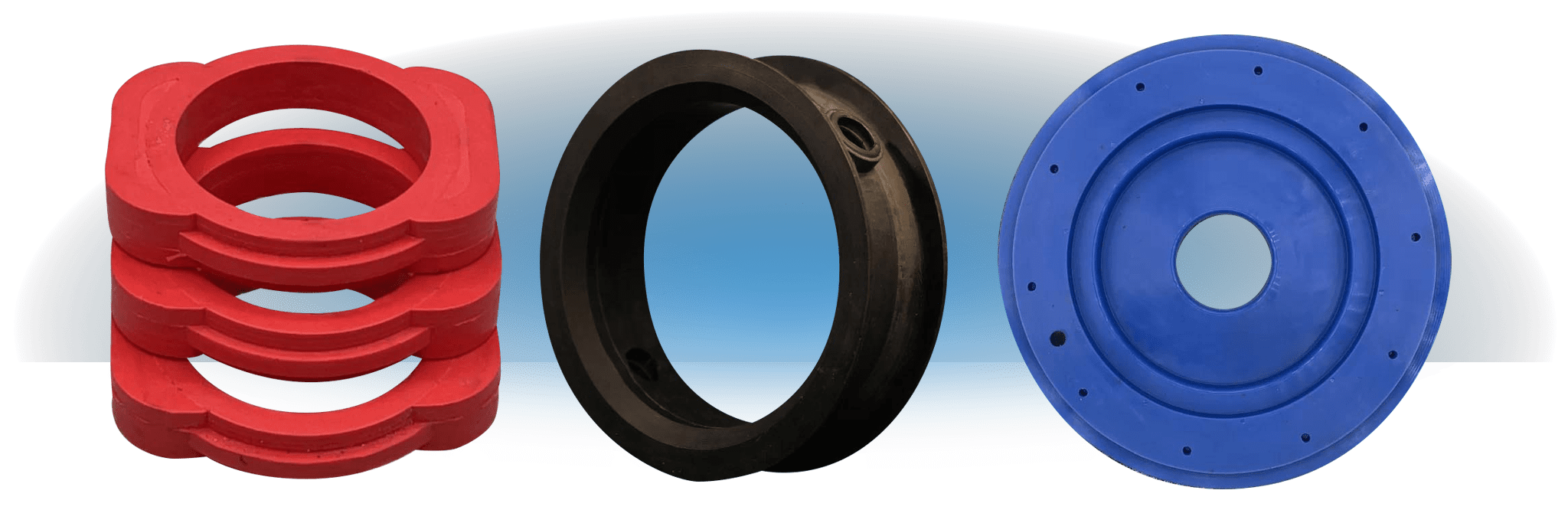

PTM can provide the precise shape, style, and quantity of rubber mouldings you require, using our extensive range of elastomeric polymers.

Our compounds are available in a variety of hardness levels, ranging from as low as 20° Shore A to 95° Shore A. Additionally, if you require a specific colour for your seals, please let us know. Certain compounds offer a wider range of colours and hardness options than others.

Many of our compounds can also be supplied to meet industry standards such as FDA, EC1935, WRAS, DTD, or specific ASTM specifications.

Experienced Rubber Moulding Team.

To match your needs exactly; together with our compounders, we can even develop application specific compounds. Our team are experienced in moulding our full range of materials.

This includes our specialist grades such as.

- perfluoroelastomers

- EMI/RF shielding compounds

- carboxylated nitrile

- high performance silicones and fluorosilicones.

Our team will work with you to offer a competitive, high quality, rapid production process.

Whether your requirement is for a one off seal, or thousands of parts.

We know that the solution to your requirement is achievable. Over the last 45+ years, our dedicated rubber moulding team has amassed a wealth of experience in rubber moulding, so, from initial design through development to implementation, we can help.

Example of specialist compounds.

- Green FDA compliant Viton™

- 25 Sh A silicone

- 35 Sh A metal detectable silicone

- 30 Sh A neoprene

- FDA compliant FFKM

- Pillarbox red silicone

- Thermo-chromic silicone

- Black FDA Aqueous EPDM

- Silica free Butyl

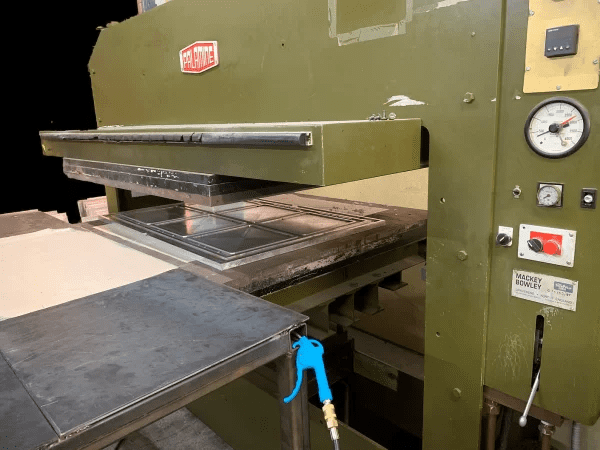

Rubber Moulding Presses.

Our moulding presses range from 16″ (400MM) to 39″ (1000MM) and we have around 4,000 mould tools to choose from.

These include sheet and pad moulds for those low volume specific requirements, which maybe useful when you have a requirement for a specific hardness or colour, not available in calendared sheeting.

We also have a huge range of standard tools to mould O-Rings and backup rings.

Our selection of ring moulds are particularly suited when using higher priced polymers for gaskets as you don’t incur any waste from the “centre”. Therefore saving on the cost.

We also have a large range of “manway” and lid seal tools to produce OEM compatible parts quickly and efficiently from our complete range of compounds.

Our two ovens are used for post-curing elastomers when required. This ensures materials such as silicones and fluoro-elastomers achieve a perfect cure.