Sponge and Foam are ideal materials for low pressure sealing applications for liquids and air.

They are also used for preventing damage to parts.

Sponge – Noun

A piece of a soft, light, porous absorbent substance originally consisting of the fibrous skeleton of an aquatic invertebrate but now usually made of synthetic material, used for washing and cleaning.

mass noun A soft, light, porous substance used as padding or insulating material.

‘the headguard is padded with sponge’

Foam – Noun

A mass of small bubbles formed on or in liquid, typically by agitation or fermentation.

A lightweight form of rubber or plastic made by solidifying liquid foam.

Source: OED.

No wonder there is sometimes confusion when people are trying to differentiate between sponge and foam. The main thing here, and it is only a general rule, is that sponge usually consists of open cells that absorb either air, liquid or moisture whereas foam is generally made of closed cells that repel air or moisture.

However it should be noted that when closed cell foam is compressed and the cells pop, it then takes on the characteristics of sponge as the cells are now open!

Fortunately with over 45 years experience in the sealing sector we are able to advise on the correct material for your application.

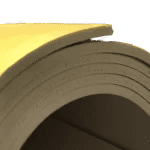

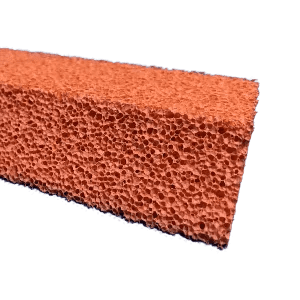

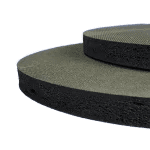

Open Cell

Open cell sponge and foam’s have excellent recovery and are used widely in the industrial sector for applications including, sound and vibration dampening, ejection dies for cutting formes, and product protection. Although open cell sponges will absorb air and liquids, when compressed they form an effective tight seal. We also offer a splitting service where one skin is removed from our Natural rubber open cell sponge to create strips suitable for the potato washing industry. Because air can pass freely between its cells, open cell sponge offers a high degree of compressibility and displays fast recovery upon release from compression. An open cell structure, therefore, has greater resistance to compression set, consequently making the material ideal for applications requiring repetitive loading or distortion.

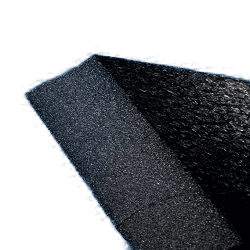

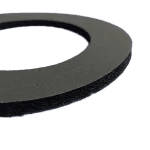

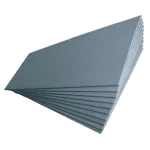

Closed Cell

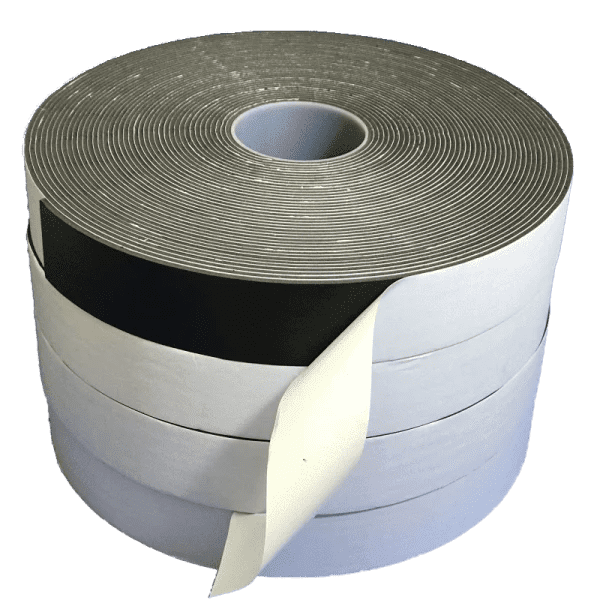

Closed cell sponge and foam’s are made through the process of foaming which creates an air filled matrix made up of cells or pockets. As these are closed, the cells repel air, liquids and moisture making an effective seal at low pressures. Closed cell sponge and foam’s are supplied in a wide range of styles, from die cut gaskets for low pressure seals, strips for weather protection and sheets. They can be supplied either plain or self-adhesive backed in our wide range of backings.

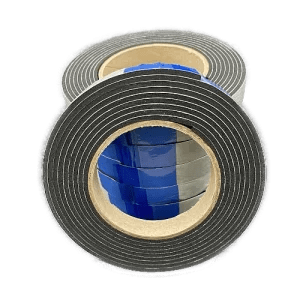

Scapa Single & Double Sided Foam Tapes

Scapa have specialist expertise in manufacturing and developing foam products for bonding, sealing, cushioning, protection, mounting and fixing applications.

The Scapa double-sided foam range provides solutions to practically every industry for bonding, mounting, fixing and joining applications. The products are economical, easy and quick to apply, clean to use, adaptable, versatile and consistent.

Scapa’s high performance double sided foam bonding materials consists of a wide range of PVC, PU and PE foams coated with a variety of adhesives. We can supply the foam tape range in a variety of formats including logs, rolls, spools, pads, discs, sheets, washers, gaskets or other die cut shapes to suit every application requirement.

Sponge & Foam

Click on the links below to download a data sheet on the different grades.

White EPDM/CR Sponge

Viton™ Sponge

Sponge Cord

Silicone Sponge

PVC Nitrile

Post Office Sponge

Polyethylene Foam

Open Cell Natural Sponge

Open Cell Expanded Pu Reticulated Foam

Neoprene/EPDM Blend Sponge

As with all sponge and foam, it is recommended that the type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.

Viton is a trademark of the Chemours Company.