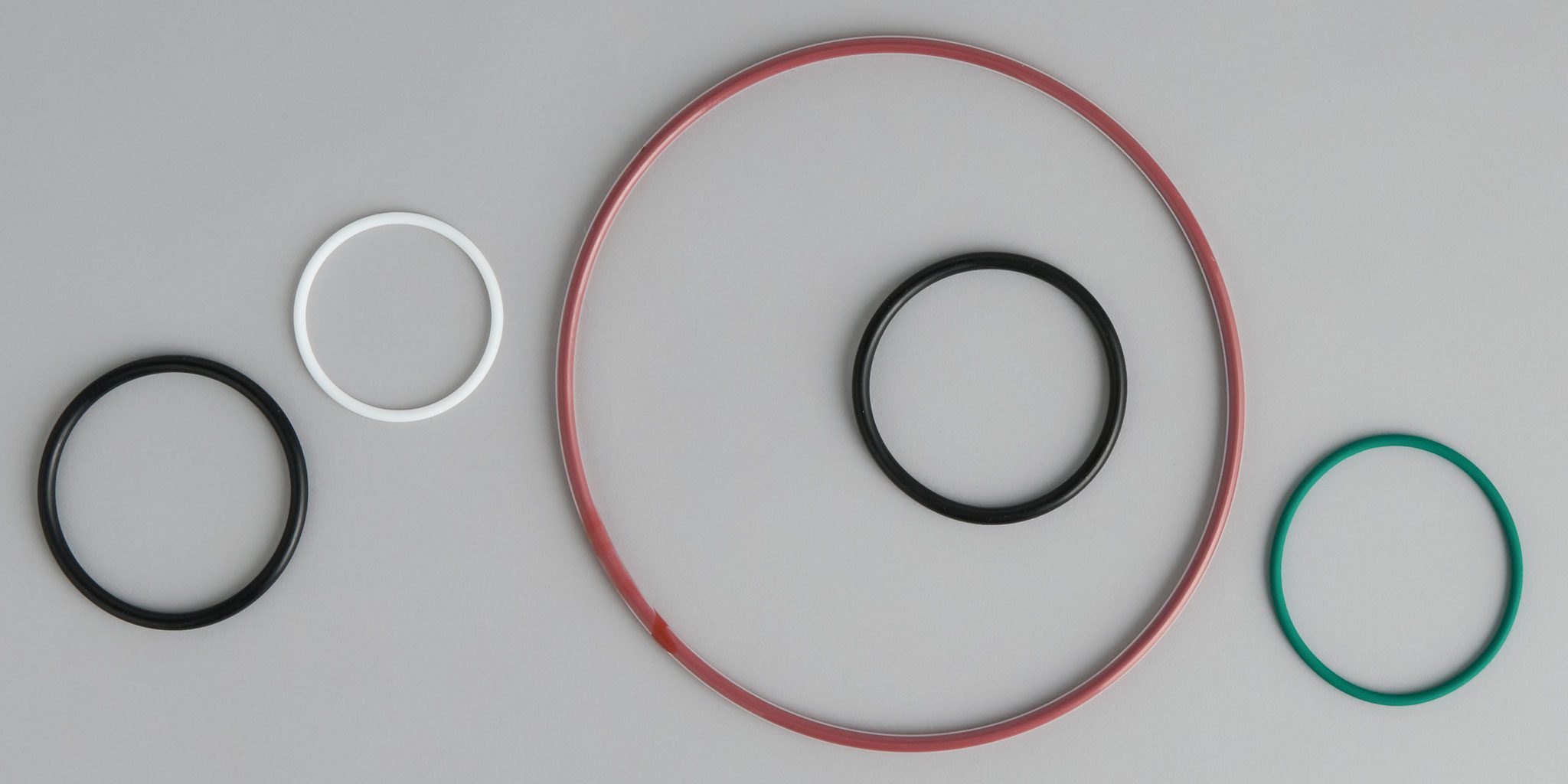

Our O-Rings Range

With our massive stocks of O-rings and quad rings in Nitrile, Viton and PTFE, you can be assured of quick delivery, when you need it.

The ‘O’ Ring is a simple, versatile, economical but essential component with a vast range of uses.

The most common of these is a static seal replacing a gasket or sealing washer, but it can also be used as a single or double acting dynamic seal.

It can be used to seal radially in both internal and external positions as well as axially on its faces. Its circular form in a variety of elastomers offers inexpensive production methods for both low and very high volumes, depending on size.

In conclusion, the ‘O’ Ring has become irreplaceable for sealing a multitude of both simple and complex applications dealing with both liquid and gaseous media.

To download our O-ring size chart, please click here

Material Selection

The most commonly used ‘O’ Ring material is Nitrile 70° Shore ‘A’ (NBR 70). This elastomer can seal the majority of “normal” industrial applications including water, oil, petrol and most mild chemicals up to 100°C and 1500psi, providing the mating surfaces and housings are adequate.

Consideration must be given for low temperatures (below -30°C), high temperatures and pressures, as well as hazardous chemicals and solvents. There is also an increasing demand for specific materials approved for use with Food Machinery (FDA), Potable Water (WRAS) and the various Gas Standards. A commonly overlooked sealing requirement is for ozone, weathering, ambient etc., where Neoprene, EPDM or Silicone perform better than Nitrile in most circumstances. In addition we also stock and manufacture O-rings in Viton, Aflas, PTFE and Perfluoroelastomers. We also supply our range of O-Rings in FDA and EC1935:2004 compliant, metal detectable grades.

With us moulding a large range of O-rings in-house, as well as a range of hardness’s we are also able to offer colour options in a wide range of polymers for ease of identification.

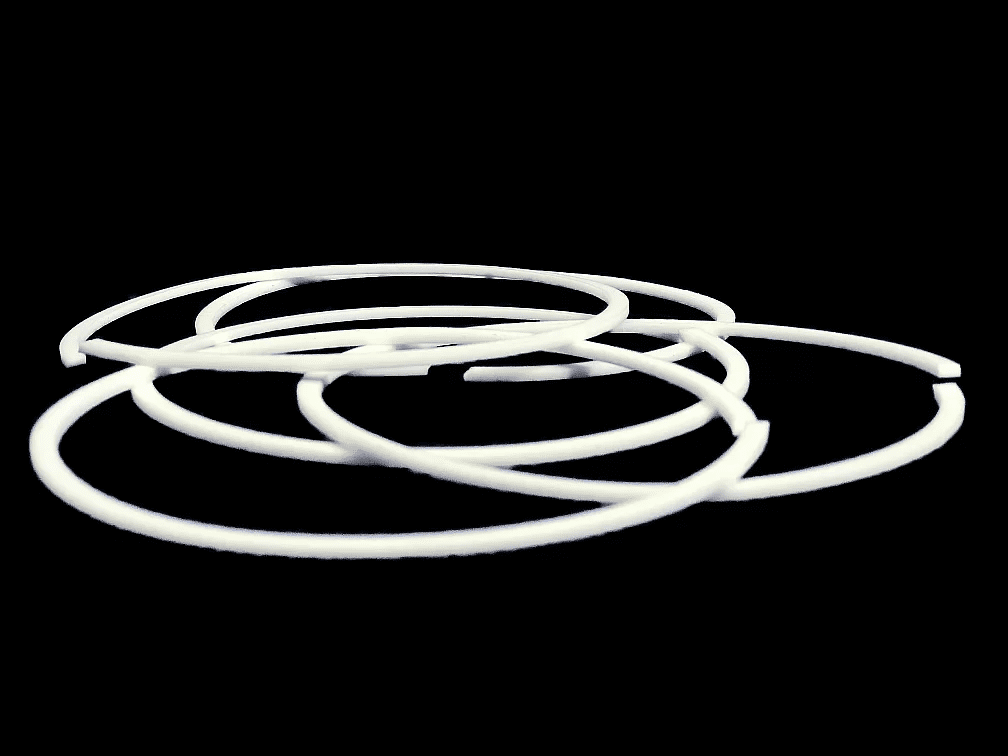

Back-up Rings

In critical high pressure situations of up to 40 bar, the stresses within the O-ring can rise sharply. We recommend the use of a profiled back-up ring in these circumstances, which is designed specifically to prevent the O-ring splitting at high pressures. Fortunately our In-House Moulding shop carries a range of tools to mould back up rings in a wide range of BS/AS standard and bespoke sizes. In addition to PTFE back up rings, we also offer elastomeric back-up rings. Typically we mould these in hard compounds including Viton, EPDM, Nitrile and specialist compounds such as Viton B (EDC – Explosive Decompression) and Aflas.

Quad Rings

These are similar to conventional ‘O’Rings and can be used in both dynamic and static applications. They generally conform in size to the BS 1806 Imperial range and use the same size grooves as the ‘O’Rings. They have several distinct advantages though; in a reciprocating movement found in both piston and rod sealing there is no likelihood of the ring twisting. Lighter radial loads are required and lubrication becomes trapped in the Quadri-Lip profile resulting in lower friction and therefore less wear and longer life. With light pneumatic applications the O.D. and I.D. “flash” present with ‘O’Rings can be a problem, resulting in poor performance – this is eliminated with Quad rings because the mould parting line is located between the lips and does not affect movement.

Quad rings can be successfully used for rotary shaft sealing, providing speeds are low and the shaft surface and lubrication is good. For static sealing the double lip affect of the Quadri-Lip will prove very beneficial.

O-Ring Assortment Boxes

Our comprehensive range of O-ring assortment boxes are ideal for engineers in the field and maintenance departments, to provide a wide choice of either metric or imperial o-rings in either Nitrile or Viton, safely contained within a robust storage box.