Click on the links below to download a data sheet on the different grades.

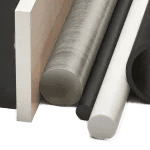

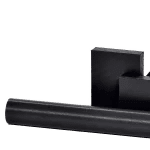

With very good wear resistance and good to excellent sliding properties, UHMWPE (Ultra High Molecular Weight Polyethylene) is used for wear strips, chain guards and in many more demanding applications.

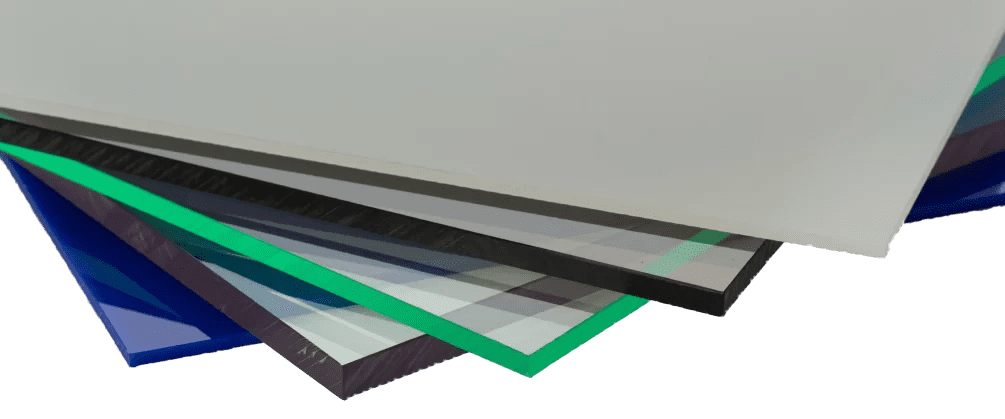

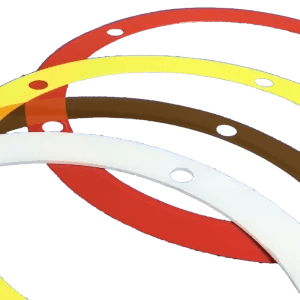

Our colour coded Plastic Shimstock is made from Polyester ( thickness from .001″ to .015″) and Polypropylene (thickness range from .015″ to .080″) to meet the particular demands of the engineering, automotive, electrical & electronic industries.

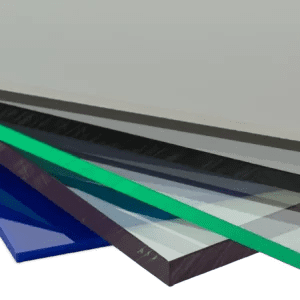

We offer 2 ranges of PVC, one is the rigid low cost, general engineering grade, and the other is our flexible PVC sheeting and rolls, commonly used for curtains retaining heat or cold. See our dedicated page here for full details on PVC Curtains & links to our dedicated website.

FDA approved with high impact resistance and excellent chemical resistance to a wide range of acids, alkali’s and solvents

PE500 is a high molecular weight polyethylene with a molecular weight of approx 500,000 g/mol, which, being a lower grade polymer, does not have the same abrasion and wear resistance characteristics as UHMW PE materials.

Polycarbonate is an extremely robust material, practically unbreakable in most applications, commonly used for machine guards and glazing applications.

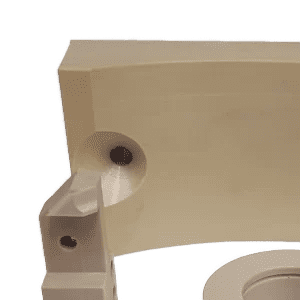

With very high temperature resistance (250 deg c constantly and up to 310 deg c for short period). Excellent chemical and high energy radiation resistance makes PEEK the material of choice for applications such as gears, valves and wear plates.

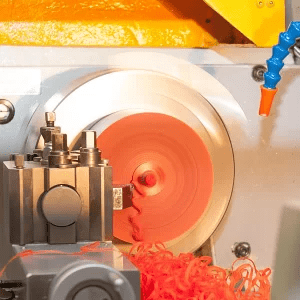

Nylon 66 has improved wear resistance, hardness and higher strength compared to 6. In addition nylon 66 has a higher melting point and reduced water absorption rate, which results in higher precision on machined parts.

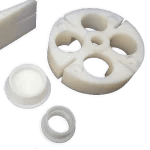

With good impact resistance and sliding properties and being easy to machine Nylon 6 can be supplied in sheet, rod or as tubes either extruded or cast.

Nylatron® GSM contains finely divided particles of molybdenum disulphide to enhance its bearing and wear behaviour without impairing the impact and fatigue resistance inherent to unmodified cast nylon grades.

FDA approved UHMW PE material with metal detectable additive. Ideal for use in food processing and packaging machinery, allowing contaminant particles to be easily found in detection systems.

Peek has high mechanical strength, excellent chemical resistance and is able to withstand high operating temperatures.

This blue metal detectable nylon is characterised by a very high tenacity, which further reduces the risk of brittle breakage of the components.

Our grey inductive detectable acetal is a metal detectable POM-C material designed for use in the food industry.

This grade of inductive detectable POM-C is modified with a metal detectable filler that provides for excellent protection in food environments that use metal detection equipment to monitor for unwanted particulates.

This Nylon 6 is internally lubricated with mineral oil filler, which improves friction coefficient by up to 50%, and wear resistance tenfold.

Having excellent optical clarity and able to be highly polished, Acrylic is often used for sight glasses and point of sale signs and dispensers.

Easily machined, Acetal is used for many applications including rollers, scrapers, gears and bearings. Acetal H can operate up to 110° C.

As with all plastics it is recommended that the type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.