Munsch & Co/PTM can supply the shape, style and quantity that you require if your process requires a rubber moulding. Available from our full range of elastomeric polymers.

Our compounds are available in varying hardness’s. From as low as 20° shore A, up to 95° shore A. Plus, if you require a specific colour for your seal, please ask. Some compounds are available in a greater colour and hardness range than others.

Many of our compounds can also be offered to meet standards such as FDA, EC1935, WRAS, DTD or specific ASTM line callouts.

Experienced Rubber Moulding Team.

To match your needs exactly; together with our compounders, we can even develop application specific compounds. Our team are experienced in moulding our full range of materials.

This includes our specialist grades such as.

- perfluoroelastomers

- EMI/RF shielding compounds

- carboxylated nitrile

- high performance silicones and fluorosilicones.

Our team will work with you to offer a competitive, high quality, rapid production process.

Whether your requirement is for a one off seal, or thousands of parts.

We know that the solution to your requirement is achievable. Over the last 45+ years, our dedicated rubber moulding team has amassed a wealth of experience in rubber moulding, so, from initial design through development to implementation, we can help.

Example of specialist compounds.

- Green FDA compliant Viton™

- 25 Sh A silicone

- 35 Sh A metal detectable silicone

- 30 Sh A neoprene

- FDA compliant FFKM

- Pillarbox red silicone

- Thermo-chromic silicone

- Black FDA Aqueous EPDM

- Silica free Butyl

Rubber Moulding Presses.

Our moulding presses range from 16″ (400MM) to 39″ (1000MM) and we have around 4,000 mould tools to choose from.

These include sheet and pad moulds for those low volume specific requirements, which maybe useful when you have a requirement for a specific hardness or colour, not available in calendared sheeting.

We also have a huge range of standard tools to mould O-Rings and backup rings.

Our selection of ring moulds are particularly suited when using higher priced polymers for gaskets as you don’t incur any waste from the “centre”. Therefore saving on the cost.

We also have a large range of “manway” and lid seal tools to produce OEM compatible parts quickly and efficiently from our complete range of compounds.

Our two ovens are used for post-curing elastomers when required. This ensures materials such as silicones and fluoro-elastomers achieve a perfect cure.

Information Request

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your moulding requirements.

MOULDINGS/COMPOUNDS

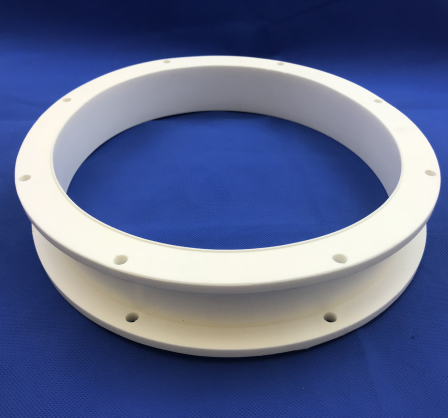

200mm Compression Seal

60° Sh A FDA Silicone.

Our range of EC1935/FDA compliant materials is extensive and includes EPDM, Natural, Neoprene, Nitrile, Silicone, Polyurethane and FKM, all available in a range of colours.

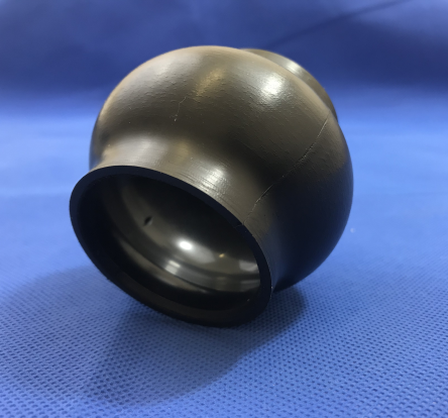

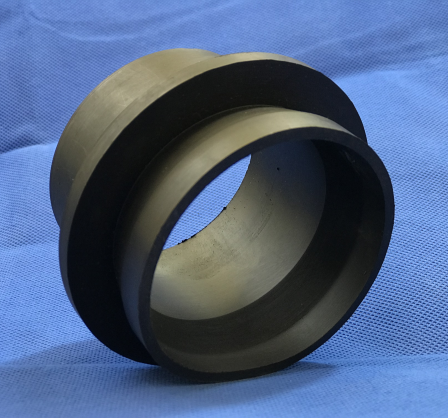

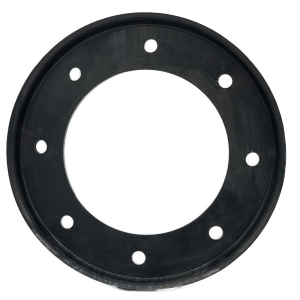

Viton™ Boot

70° Sh A Viton™ A

We offer a full range of Viton grades including, A, B, GF, and white FDA. We also carry FKM's from 40° - 90° Sh A, in a range of colours for identification purposes.

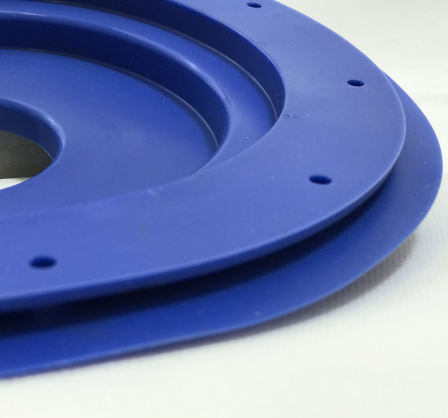

Polyurethane Diaphragm

65° Sh A Blue Metal Detectable

We can supply FDA/EC1935:2004 compliant metal detectable mouldings in a wide range of polymers, different colour options and a choice of hardness's.

Silicone Bellow

60° Sh A EC1935 Silicone

Although no rubber carries formal FDA approval, all of our FDA/EC1935 compliant grades meet the requirements set out in the latest update of CFR21 FDA 177-2600.

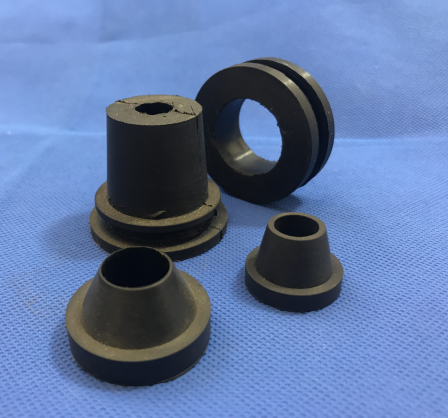

Rubber Bush

60° Sh A RIO Fluorosilicone

Our specialist compound range includes Fluorosilicone, Aflas, Perfluoroelastomer (Including FDA), DTD & ASTM grades, conductive, anti-static and high tear strength.

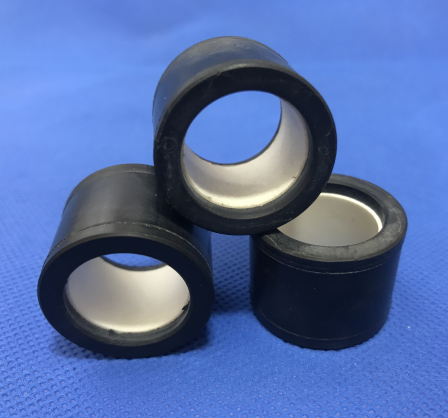

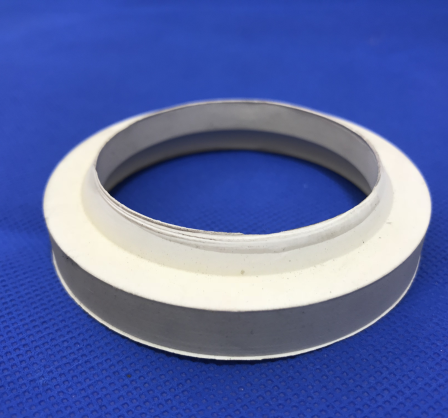

PTFE Lined Moulding

65° Sh A HNBR

Whether you require PTFE lined or rubber to metal mouldings, we supply in our extensive polymer range including hydrogenated nitrile, for improved oil resistance.

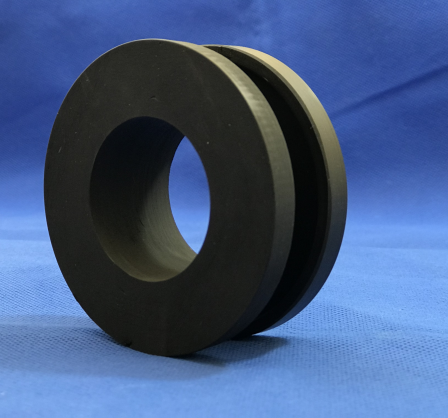

Double Lipped Moulding

55° Sh A Fluoroelastomer

Working in conjunction with our experienced toolmakers, we are able to produce simple or complex tooling in steel or aluminium to mould almost any requirement.

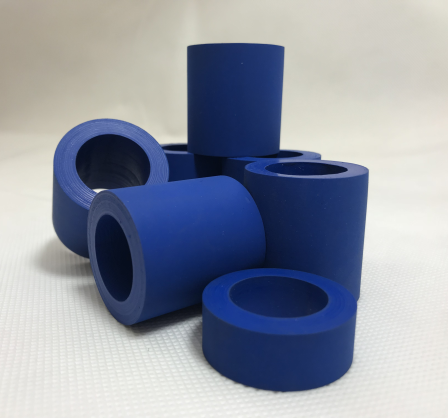

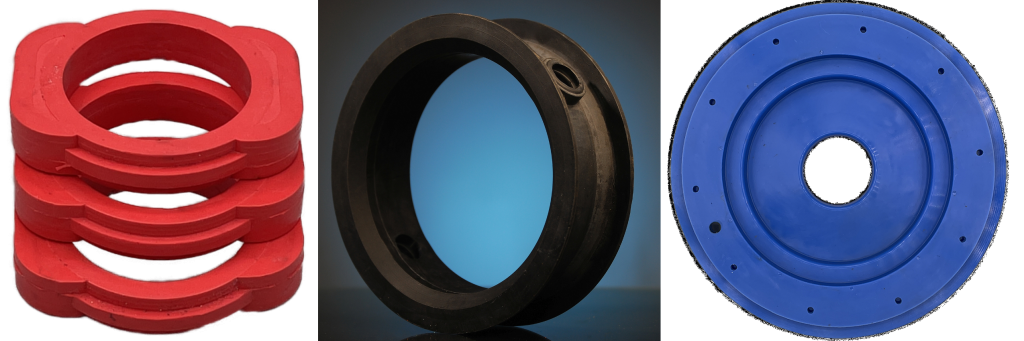

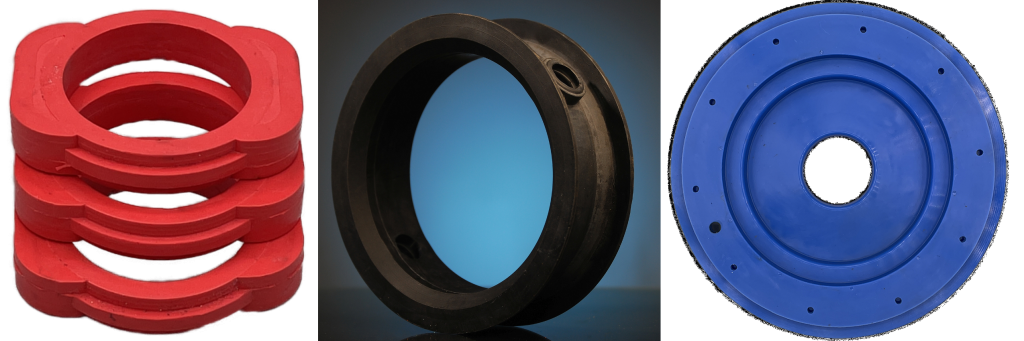

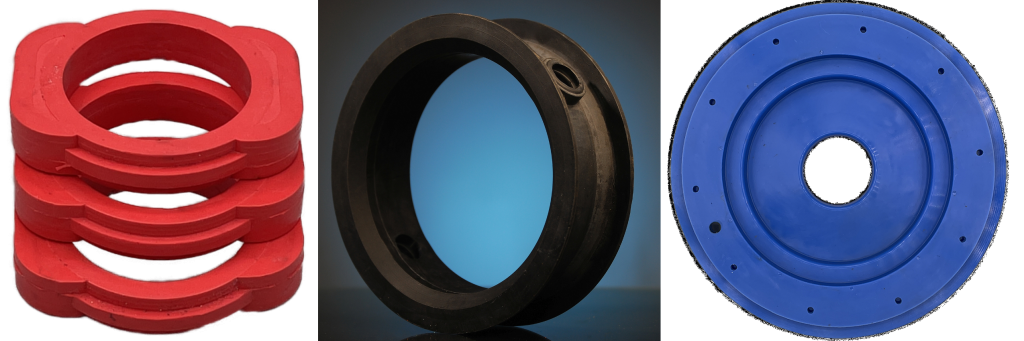

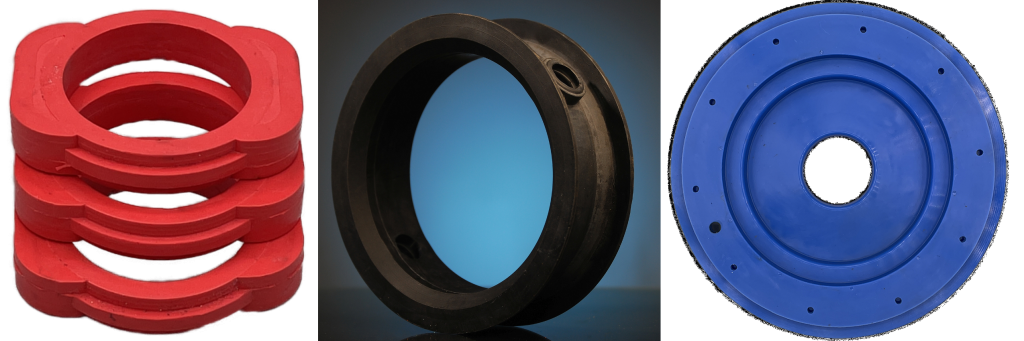

Polyurethane Bushes

80° Sh A Blue FDA Polyurethane

When it comes to abrasion resistance, polyurethane is often the material of choice. Alternatively, we also mould components in carboxylated nitrile (XNBR).

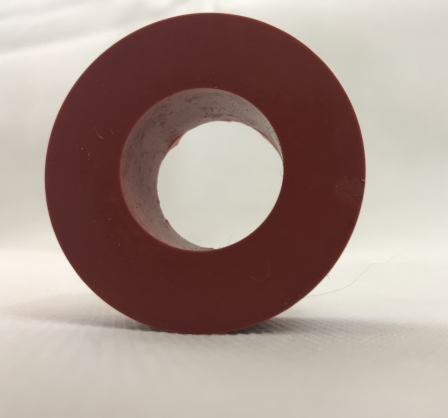

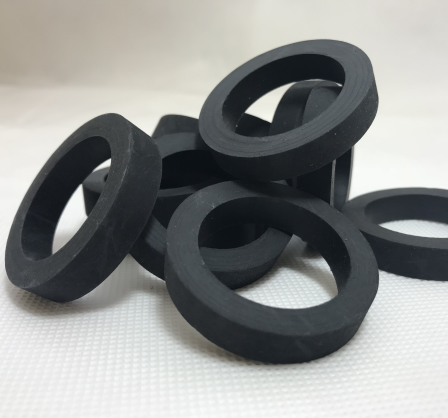

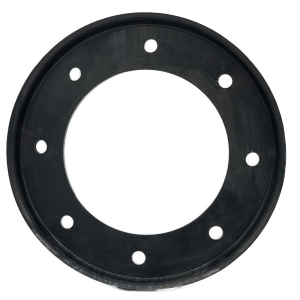

Lathe Parted Washers

65° Sh A Polychloroprene

With our selection of tube moulds (8mm - 76mm i.d. up to 112mm o.d.) we are able to mould, grind and part washers economically and quickly without the need for tooling.

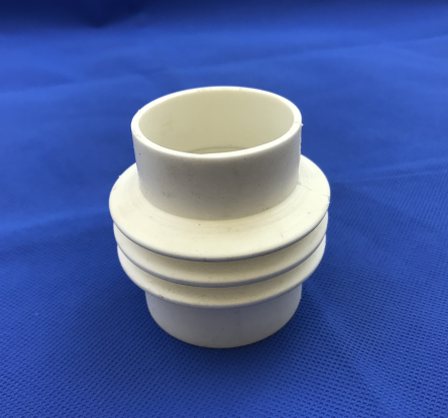

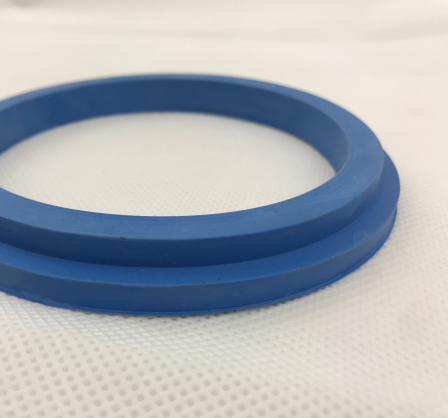

Stepped Seal

Blue 65° Sh A FDA EPDM

EPDM is excellent with ozone and steam. We carry EPDM from 30-85° Sh A in a range of colours and grades, including FDA, aqueous, anti-static and WRAS approved.

Instantaneous Coupling Seal

40° Sh A FDA Natural

We mould a variety of parts compatible with OEM equipment including lid seals, tri-clover mouldings, O-rings, Unicone seals, vac seals and camlock gaskets.

Pump Thrower

55° Sh Nitrile

We carry 22 different Nitrile compounds from 40 - 90° Sh A, in a range of colours and types including FDA blue, black and white, anti-static and peroxide cured.

Chamfered Moulding

Blue 25° Sh A EC1935 Silicone

We are able to produce mouldings in a range of hardness's from 25° Sh A for low pressure sealing applications to 95° Sh A, in our extensive choice of elastomers.