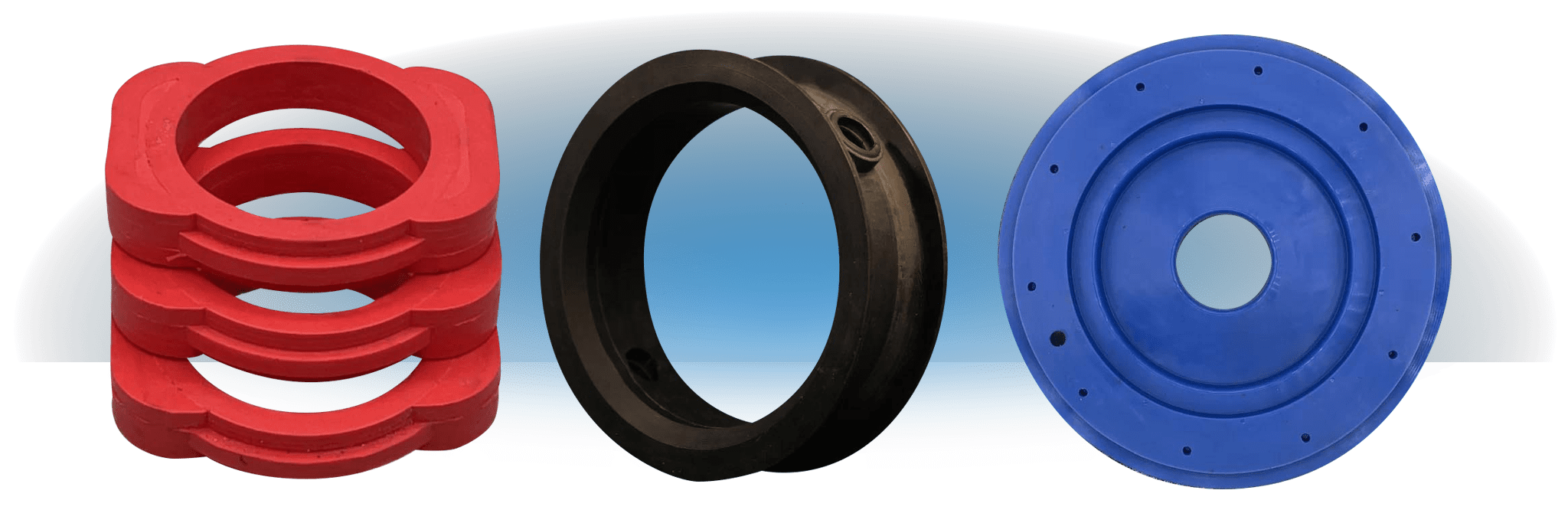

PTM supplies rubber mouldings in the exact shape, design, and quantity you need, no matter how specific the application. We work with a wide selection of elastomeric polymers, giving you flexibility in material choice and performance characteristics. Whether you need a simple profile or a complex, high-precision form, we can produce rubber mouldings that meet the demands of your project.

Our rubber compounds come in a full spectrum of hardness ratings, from as soft as 20° Shore A up to a firm 95° Shore A. This range allows us to produce rubber mouldings suited for everything from vibration isolation to high-pressure sealing. If you require a particular colour, just let us know—some compounds are available in a broader range of colours and hardness combinations, which can be matched to your brand or technical needs.

We also understand that compliance matters. That’s why many of our rubber compounds can be manufactured to meet specific industry standards, including FDA for food contact, EC1935 for European regulations, WRAS for water safety, DTD for aerospace, and ASTM requirements for various technical applications. With PTM, you can be confident that your rubber mouldings will not only perform well but also meet the standards required for your sector.

Experienced Rubber Mouldings Team.

To match your needs exactly; together with our compounders, we can even develop application specific compounds. Our team are experienced in moulding our full range of materials.

This includes our specialist grades such as.

- perfluoroelastomers

- EMI/RF shielding compounds

- carboxylated nitrile

- high performance silicones and fluorosilicones.

Our team will work with you to offer a competitive, high quality, rapid production process.

Whether your requirement is for a one off seal, or thousands of parts.

We know that the solution to your requirement is achievable. Over the last 45+ years, our dedicated rubber mouldings team has amassed a wealth of experience in rubber moulding, so, from initial design through development to implementation, we can help.

Example of specialist compounds.

- Green FDA compliant Viton™

- 25 Sh A silicone

- 35 Sh A metal detectable silicone

- 30 Sh A neoprene

- FDA compliant FFKM

- Pillarbox red silicone

- Thermo-chromic silicone

- Black FDA Aqueous EPDM

- Silica free Butyl

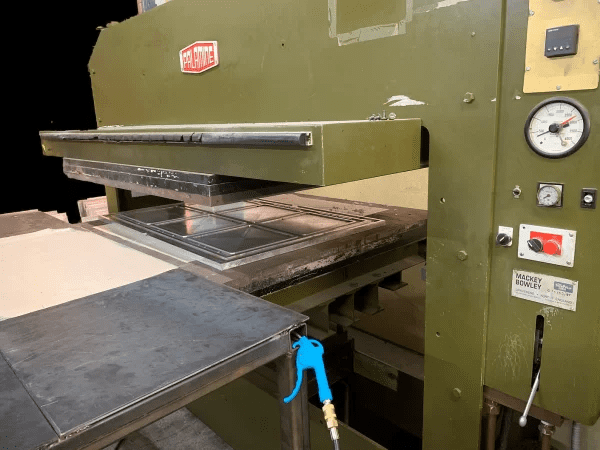

Our moulding presses range from 16″ (400mm) to 39″ (1000mm), and we hold a library of around 4,000 mould tools suitable for a wide variety of rubber mouldings.

This includes sheet and pad moulds ideal for low-volume or highly specific requirements—particularly useful when you need a unique hardness or colour not available in standard calendared sheeting.

We also stock an extensive range of standard tools to mould O-rings and backup rings.

Our selection of rubber mouldings is especially cost-effective when working with high-value polymers for gaskets, as the design eliminates waste from the centre—cutting down on material costs.

Additionally, we have a large stock of “manway” and lid seal moulds to produce OEM-compatible parts efficiently, using our full range of elastomer compounds.

When required, we use our two curing ovens for post-curing elastomers. This ensures materials like silicones and fluoroelastomers achieve full crosslinking for long-term performance and reliability.