Thermiculite 894 is a highly specialised sealing solution within the Thermiculite range, developed for critical service in extreme industrial conditions. Unlike conventional packing, this flexible gasket material maintains performance under severe thermal and chemical stress, offering dependable sealing where other products fail.

Manufactured using Flexitallic’s advanced Thermiculite technology, 894 is created by over-knitting strips of Thermiculite foil with ultra-fine Inconel 600 wire (0.09mm diameter). These reinforced strips are then braided together to form a robust square-section material, supplied in continuous coil form. This unique construction ensures durability, thermal stability, and resistance to oxidation and aggressive media.

Performance

Technical Capabilities

- Oven door seals in industrial processing

- Large diameter flanges on reactors and pressure vessels

- Fertiliser production plants

- High-temperature valve stem sealing systems

- Header rings in valve stacks, providing oxidation protection for graphite components

- Form: Square-section continuous coil (rectangular cross-sections available on request)

- Maximum Service Temperature: 1050°C (1920°F)

- pH Range: 0 to 14

Please see the datasheet for full details.

Important: This material is not intended for use as a facing in Flexitallic Flexpro™ gaskets. Final suitability for any application remains the responsibility of the customer. For technical assistance, please contact our team.

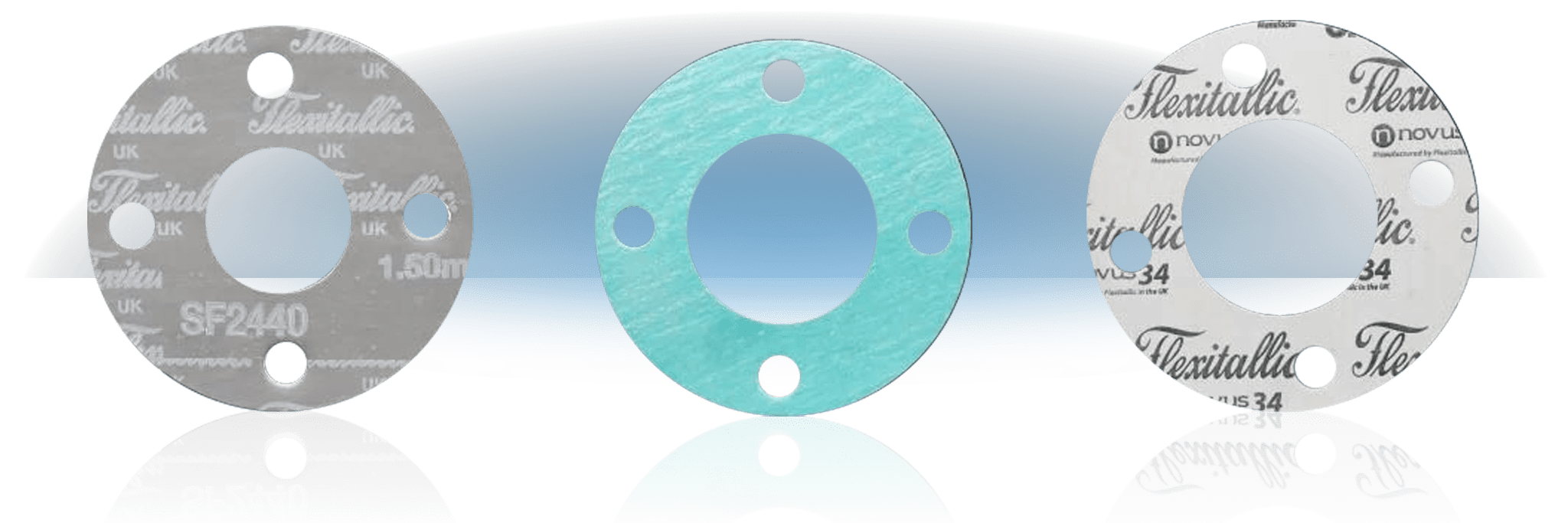

Other Types of Thermiculite

With such a wide range of stocked materials, see below for an overview of each material and click on the link for a data sheet.

Thermiculite 715

Made from chemically and thermally exfoliated

vermiculite, reinforced with aramid and synthetic

fibres, and bound with premium nitrile rubber.

As with all types of fibrous sheeting, it is recommended that the type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.

Thermiculite 894 FAQs

Contact Us

Telephone : +44 (0)1625 573971

Out of hours number: +44 (0)7479778989

Email: sales@epdm.co.uk