6 Things to Consider Before Choosing a Gasket Manufacturer

Skip to

Industrial processes requiring the transport of substances from liquid to gas and solid may call for gasket sealing solutions to overcome leakages.

Small factors like the size of a gasket and its ability to resist wear and tear play considerable roles in stopping the escape of water, gas, and other fluids.

Gaskets are installed between two surfaces to act as a channel regulating fluid movement. Even when the two surfaces are not smooth, a gasket can compress to close the gaps and eliminate leakage. With so many gasket manufacturers in the industry, it can be challenging to determine which brand offers the highest quality products.

Here are six things below to consider before choosing a gasket manufacturer.

Nature of Gasket Material

There are metallic gasket manufacturers, non-metallic and semi-metallic brands. Metallic gaskets are ideal for harsh temperature applications.

Also referred to as ring gaskets, metallic gaskets form an initial line contact; they can contain fluid flow through wedging when two connective surfaces touch. The octagonal cross-sections of metallic gaskets offer extra strength in the event of high pressure. For most oil and gas applications, metallic gaskets are typically preferred. On the other hand, if you are looking for gasket material for low pressure and low-temperature environments, you may want to buy non-metallic ones.

Flange Design

Other crucial factors include the flange material and its design.

Fragile flange materials such as plastic and glass need gaskets that can handle low bolt loads. On the other hand, metallic flange materials will require gaskets materials that seal well with high bolt loads.

Get in touch with us to discuss your flange design requirements.

Wear and Tear

The rate of degradation of gaskets is also a significant factor to consider when choosing your gasket manufacturer. Seals and gaskets may fail if you buy the products from low-quality suppliers. It helps to look for seals and gaskets with longer service life, as this would minimise their wear and tear and save you money on maintenance costs.

We will help you choose the best seals and gaskets that will get the job done perfectly. When you order high-quality gaskets from ourselves, you will get excellent value for money.

Dimensions

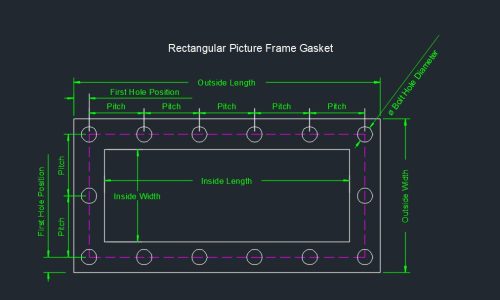

Consider basic parameters such as the numbers and bolt sizes (that require indents or holes) and the thickness, pipe size, and outer and inner diameters.

You can ask your engineering team to write down these dimensions and find out from the gasket manufacturer any other relevant dimensions.

Compatibility and Applications

You don’t want to buy gasket materials from a manufacturer to find out that they are incompatible. Where your machine is flushed, the type of fluid used in the process should all be fine-tuned to ensure that you eliminate the risks of premature degradation of the gasket material.

Also, you may want to consider whether the application needs conductive materials to be used in the gasket—manufacturers design gaskets for several applications like separating liquids (including water, oil, and chemicals). You can also use gaskets to protect sensitive equipment from electromagnetic interference and the separation of toxic gases.

Type of Gasket

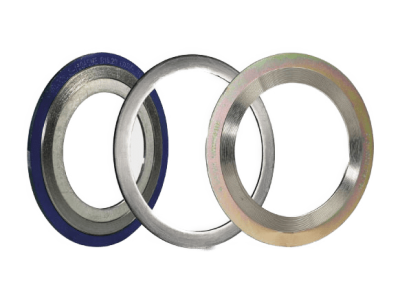

Once you know the specific type of suitable material for the end application, you will have to pick a manufacturer that sells the gasket’s right type (structure). Popular examples include jacketed, solid, and spiral wound gaskets. Jacketed gaskets come with a soft non-metallic interior and coating. These are available in several varieties like single and double jackets. The metallic coating provides non-metallic gaskets with good resistance to damage.

Solid metal gaskets are more durable, but they demand a higher compression force to create an effective seal. Spiral wound gaskets have windings of metallic materials combining resistance and flexibility. If you use piping and pumping systems, spiral wound gaskets will provide a reliable seal. Finally, you can also consider Kammprofile gaskets as these create a tight seal along the edges of the gasket; they can be repaired with ease.

Choosing the best supplier is vital for guaranteeing the material success of your project. Therefore, select a gasket manufacturer with a high level of experience in building gaskets for your industry or target market. Contact us today to discuss your gasket requirements.

Related articles

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.