PTFE

Gaskets and seals

PTFE

Gaskets and seals

Table of Contents

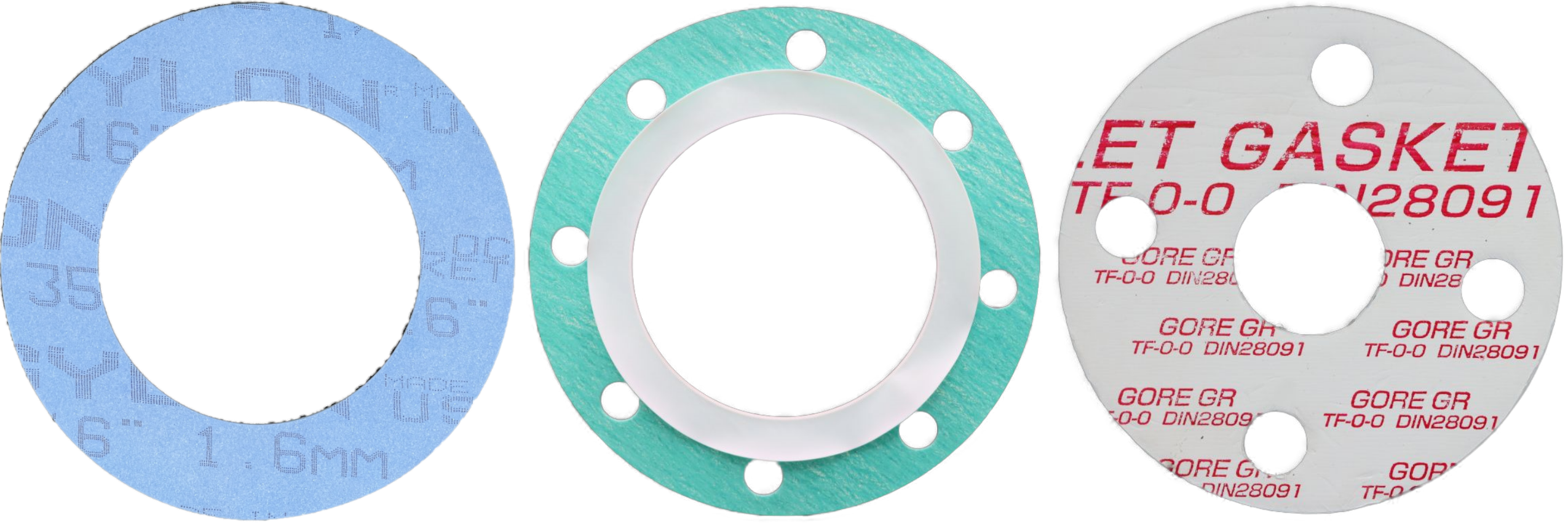

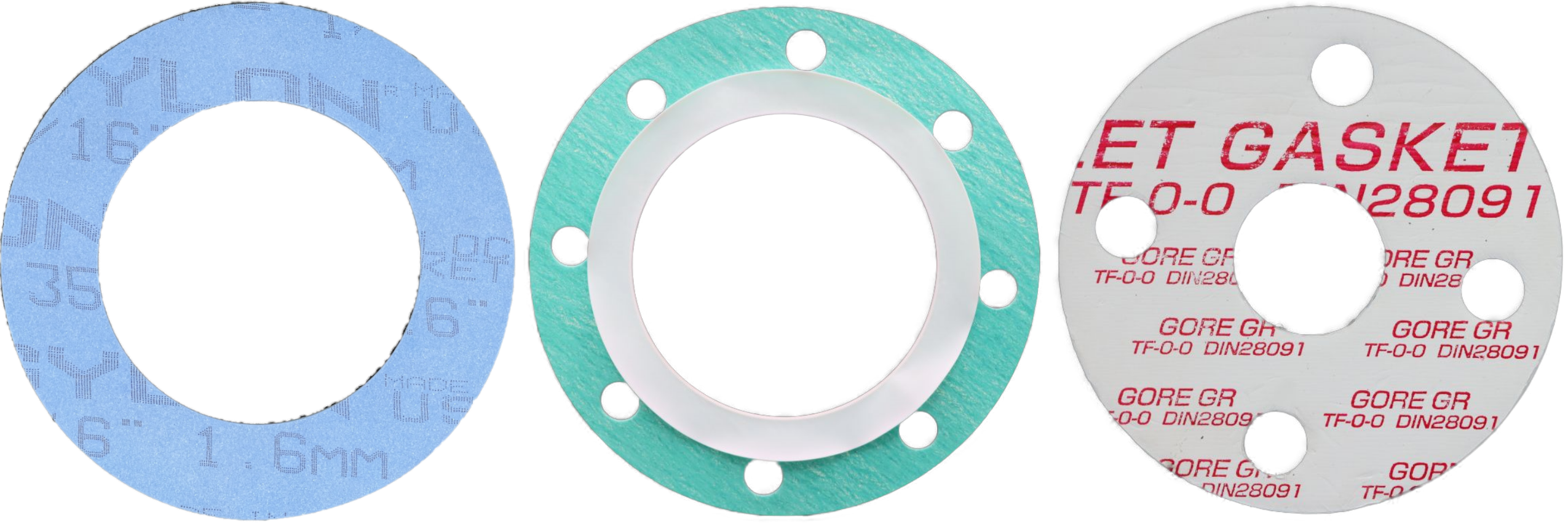

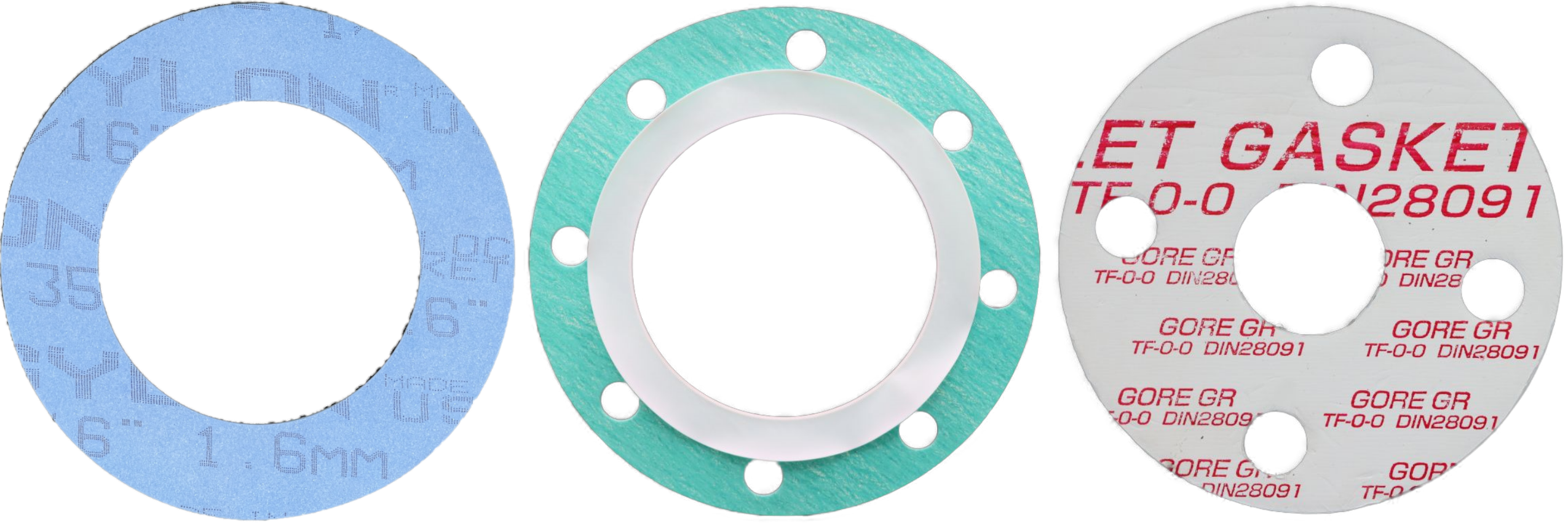

We manufacture PTFE Gaskets from our complete range of Polytetrafluoroethlyene (PTFE) materials. Commonly referred to as Teflon (The well known brand name of The Chemours Company), PTFE has outstanding resistance to chemicals, a wide temperature range, withstanding (–200° C to +260° C) and excellent dielectric properties.

Being chemically inert, except for some alkaline metals, means PTFE Gaskets are the seals of choice in food, pharmaceutical and chemical sectors.

PTFE can be divided into two main styles. Virgin PTFE, which is fairly hard, like plastic, however it will still compress to make a seal between two faces. Expanded PTFE is more like a sponge, making it ideal for sealing damaged, glass or plastic flanges because it compresses more easily than the Virgin grade.

As one of the largest gasket cutters in the United Kingdom, we make and supply PTFE gaskets in a broad range of different variants including, etched and filled grades.

We also manufacture PTFE Envelope gaskets in-house. The PTFE Envelope is fitted on the inside diameter (bore) of the gasket. The gaskets are usually made from non-asbestos fibre or rubber. The advantage of this style of gasket is that it combines the inertness of PTFE with the mechanical properties of the outer gasket. Above all, because the envelope only covers the bore, it saves you the expense of a complete PTFE gasket.

Main Benefits of PTFE

- Low coefficient of friction

- Excellent chemical inertness

- Non-adhesive surface

- Wide temperature range withstanding (–200° C to +260° C)

- Excellent dielectric properties

- Filled grades available

- Can be supplied etched, if bonding is required

- Most grades are both FDA/EC1935:2004 and WRAS Compliant

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your rubber gasket requirements.

PTFE Gaskets Enquiry Form

Grades of PTFE that we manufacture Gaskets from

Grades of PTFE that we manufacture Gaskets from

Click on the links below to download a data sheet on the different grades.

Unbranded PTFE

PTFE is considered one of the most stable materials from the thermal point of view. Up to a service temperature of 260° C PTFE does not change its own physical and molecular properties.

PTFE is commonly used for lining tanks and etched PTFE allows the sheets to be glued on to surface of various materials, such as metal, rubber, plastics. The etching process comprises of a chemical surface treatment on filled or virgin PTFE.

We make glass fibre, carbon, bronze and graphite filled PTFE gaskets, for enhanced properties or resistance. The datasheet gives a breakdown of the benefits of each filler and typical applications.

This grade is suitable for use in food and beverage applications because it is compliant with FDA and EC1935:2004. It is resistant to many chemicals and ozone. It can be used at temperatures up to 115° C.

As an authorised Garlock distributor we carry the complete Gylon® range to be converted into gylon gaskets. Visit our dedicated Gylon® page, or see below for links to data sheets on each style.

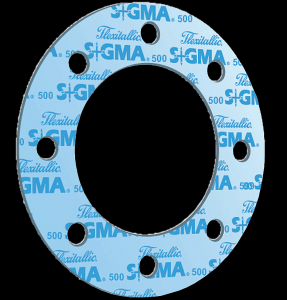

Probably the most talked about material in the Gylon range, this PTFE with Aluminosilicate microspheres meets FDA specifications and is suitable for use with acids, some caustics, refrigerants and cryogenics.

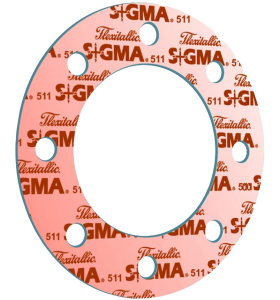

This Fawn Gylon with Silica can be used with Strong acids (except hydrofluoric), steam, solvents, hydrocarbons, chlorine and cryogenics. It meets FDA, ABS and USDA specifications.

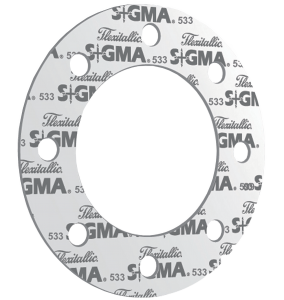

Suitable for use with Strong acids (except hydrofluoric), steam, solvents, hydrocarbons,

chlorine and cryogenics. This grade meets the following specifications: BAM, FDA, KTW, and TA-Luft.

PTFE with barium sulphate, resistant to strong caustics, moderate acids, chlorine, gases, water, steam, cryogenics, hydrocarbons and

aluminium fluoride.

This FDA compliant, PTFE gasketing material is designed to compress and conform to irregular or damaged surface. This makes it suitable for flanges that generate lower stresses, such as lined flanges and equipment.

A micro-cellular PTFE but with a rigid PTFE core for improved handling. This style is suitable for glass-lined, or damaged flanges, it will conform under much lower pressures.

ENVELON™ is a high performance, aluminosilicate microsphere filled PTFE gasketing material which is designed to compress and conform to irregular surfaces, giving it a tight seal on glass-lined and wavy flanges.

Provide a durable and safe solution for protecting the integrity of food and pharmaceutical processing media. Their modified and restructured PTFE material is pre-formed and stress controlled for all standard TRI-CLAMP connections.

Flexitallic PTFE Grades

This PTFE with hollow glass micro-spheres makes it suitable not just for use in standard metallic flanged connections but also in load compromised bolted connections. It complies with both WRAS and FDA.

The silica filler in this style of PTFE makes it suitable for sealing most chemicals across the whole pH range (0-14) with the exception of molten alkali metals, fluorine gas, hydrogen fluoride or materials which may generate these.

A high performance bi-axially orientated sheet sealing material containing PTFE with barium sulphate (barytes) filler. It is particularly suitable for use in applications involving strong alkalis.

Sigma® 588 comprises of soft micro-cellular PTFE faces sintered onto a rigid pure PTFE core which enhances handling and installation of large or complex gaskets.

Klinger & Gore PTFE Gaskets

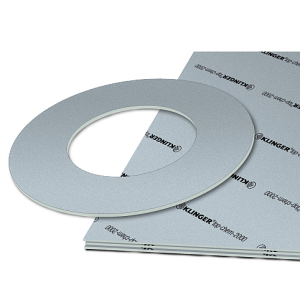

Excellent sealing at high temperatures and pressures, ideal for aggressive chemicals, easy to handle and cut, creep resistant. Firesafe API 6FA, BAM Approval for use with oxygen 100 bar / 2000C.

This style is ideal for maintaining a tight seal even at low surface loads and temperatures.

It has excellent chemical resistance in strongly acidic and alkaline applications.

Top-Chem-2006 has good chemical resistance in strongly alkaline conditions and good mechanical properties at medium and low temperatures and loads.

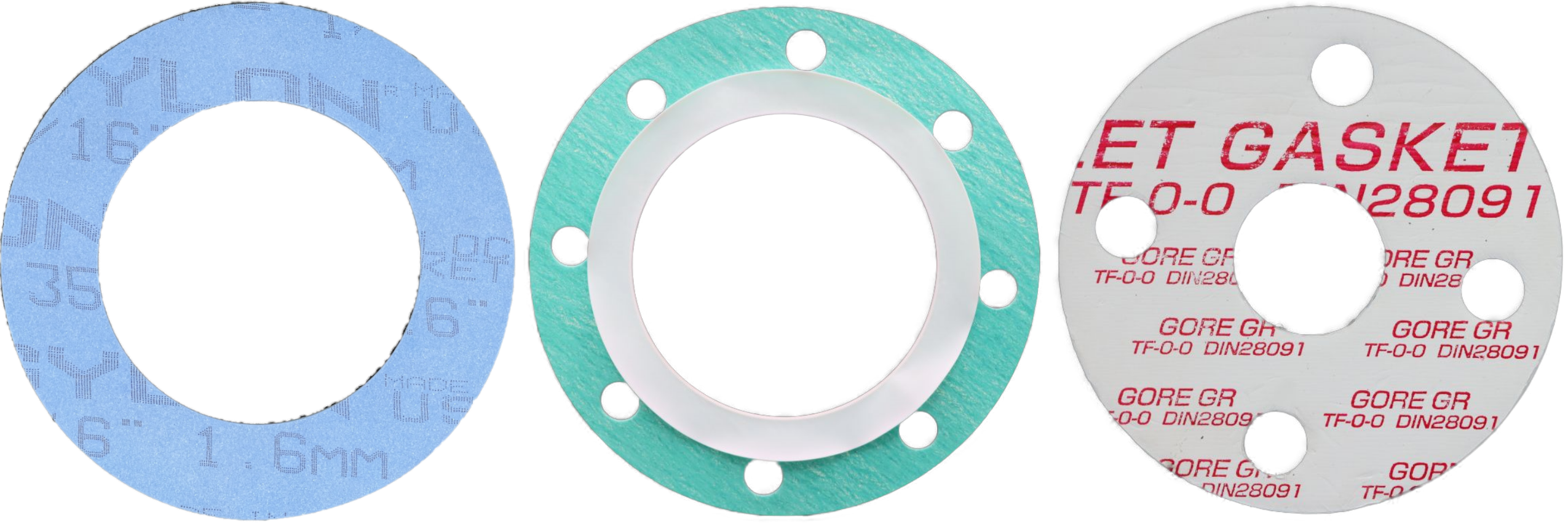

Gore GR is exceptionally resistant to creep, cold flow and aggressive media. This 100 % ePTFE gasket sheet reliably seals steel piping and equipment. It has a maximum temperature range of -269°C to 315°C.

As with all types of gaskets, it is recommended that the material type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.