- Home

- »

- Quality Sealing Materials

- »

- Rubber

RUBBER

GRADES

Table of Contents

Rubber is an extremely versatile material with excellent sealing capabilities, however it is important to note that rubber can vary greatly in terms of performance and quality.

With this in mind W.C. Munsch/PTM only supply rubber from reputable European suppliers thus ensuring that our qualities are of a high standard.

In addition to our commercial rubber range we carry a number of British Standard and other specification rubbers such as WRAS Approved, NCB158, ICI M228 etc.

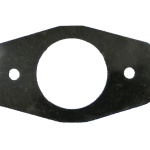

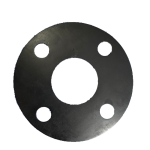

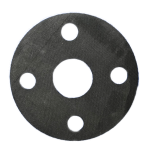

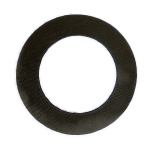

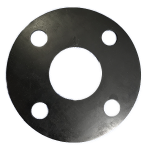

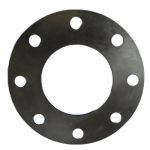

The material is commonly used to produce one of our most popular products, rubber gaskets.

Specification Rubber is made to exacting standards as outlined in BS1154, BS2751, BS2752, BS476, BS5400 etc. For detailed information on specifications please phone us, or click here to see the British Standards web site.

It is important to ensure that the correct material is used for the application. i.e. Although Nitrile is a rubber with very good properties when used in an oil environment, commercial Nitrile would fail quickly when used with fuels, especially bio-fuels.

Having witnessed an increase in suppliers stocking an ever expanding range of “economy” grades of rubber over the last few years, it is reassuring to know that there is a company with over 45 years experience in the sealing sector who will advise you of the most suitable material for your application.

The table below can be used as a guide to identify the most suitable rubber for each application but please call us to ensure application specific criteria is met.

Chemical Resistance Guide

| Butyl | EPDM | CSM | Natural/SBR | Neoprene | ||

| Physical Properties | Resilience | F | G | G | VG | G |

| Compression Set | F | F | F | G | G | |

| Impermeability to Gases | VG | G | VG | F | G | |

| Mechanical Properties | Impact Resistance | G | G | G | VG | G |

| Abrasion | G | G | G | VG | G/VG | |

| Tear | G | F | F | VG | G | |

| Chemical Resistance | Weather | VG | VG | VG | F | G |

| Ozone | G | VG | VG | U | G | |

| Dilute Acid | VG | VG | VG | G | F | |

| Dilute Alkali | VG | G | VG | F | F | |

| Lubricating Oils | P | P | F | U | F | |

| Petrol* | P | P | P | U | P | |

| Degreasing Solvents | P | P | P | U | P | |

| Polar Organic Solvents | G | G | F | F | P | |

| Hydraulic Oil (Silicone) | F | F | G | P | G | |

| Hydraulic Oil (Phosphate Esters) | G | G | F | U | U | |

| Working Temperature | Minimum °C | -25 | -40 | -35 | -40 | -30 |

| Maximum °C | 120 | 140 | 125 | 70 | 110 |

| Nitrile | Polyurethane | Silicone | Viton A® | ||

| Physical Properties | Resilience | G | G | P | F |

| Compression Set | G | G | G | G | |

| Impermeability to Gases | G | G | P | VG | |

| Mechanical Properties | Impact Resistance | F | G | F | G |

| Abrasion | G | VG | F | G | |

| Tear | G | VG | P | F | |

| Chemical Resistance | Weather | F | VG | VG | VG |

| Ozone | P | VG | VG | VG | |

| Dilute Acid | G | P | F | G | |

| Dilute Alkali | F | P | F | G | |

| Lubricating Oils | G | VG | G | VG | |

| Petrol* | P | P | P | G | |

| Degreasing Solvents | P | F | F | G | |

| Polar Organic Solvents | P | F | G | G | |

| Hydraulic Oil (Silicone) | G | F | F | G | |

| Hydraulic Oil (Phosphate Esters) | P | F | F | P | |

| Working Temperature | Minimum °C | -30 | -40 | -70 | -30 |

| Maximum °C | 115 | 90 | 200 | 250 |

VG = Very Good: G = Good: F = Fair: P = Poor: U = Unsuitable: Petrol* Since refiners and blenders have been increasing the percentage of bio-fuel (Usually Ethanol) in petroleum and diesel it is recommended to always test the proposed rubber with the fuel first. These ratings are intended as a general guide to the suitability of the rubber. Individual compounds vary. For specific information or to match criteria simply call or e-mail us.

Simply give us a call or fill in the enquiry form below and one of our experts will give you all the advice and guidance to meet your rubber requirements.

Rubber Enquiry Form

Types of Rubber

Click on the links below to download a data sheet on the different grades.

Butyl/EPDM and CSM

Natural Rubber

Chloroprene/Neoprene Rubber

Nitrile Rubber

Silicone

Viton™/FKM

As with all elastomers it is recommended that the type is tested for suitability as grades do vary.

We are happy to advise on any application, but final responsibility lies with the customer.

Viton is a trademark of The Chemours Company.