How do we make rubber bushes?

Rubber bushes are an important product in our range.

We supply rubber bushes, up to 300mm long, as calendared rubber sheet is not generally available thicker than 50mm (2″)

The other advantages of moulded and lathe parted rubber bushes are as follows:

- Minimal wasteage compared to cutting from sheet.

- Much wider range of compounds available for specific requirements.

- Concentric finish, even on small bushes/washers.

- Economical, as they don't need a bespoke mould tool.

Where are rubber bushes used?

Rubber bushes are used in a huge range of environments, from automotive, both current and classic vehicles, machinery, spacers for a variety of reasons etc. etc.

The list is practically endless.

How do we make rubber bushes?

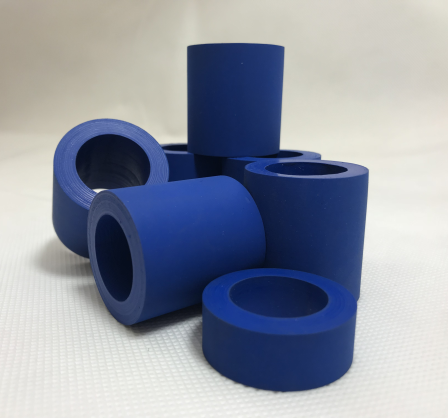

We have a comprehensive range of moulds, where we mould a rubber tube with the inside diameter (I.D.) correct and the outside diameter (O.D) oversize. Once moulded, and post-cured, if required, we then use our grinding lathe to reduce the O.D. to the required diameter.

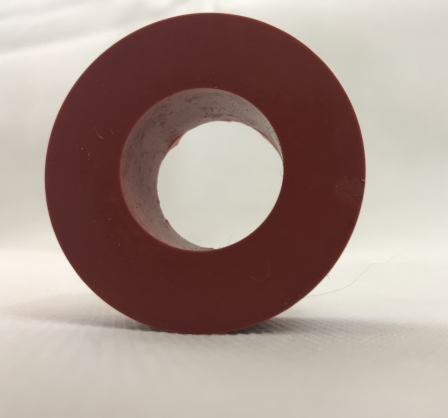

Once this has been done and quality control checked, we then part the bushes/washers off on another lathe resulting in a concentric, cost effective part.

Why do we make rubber bushes this way?

There are many reasons why we produce rubber bushes this way.

Some of the main ones are highlighted below:

- By utilising our existing tube moulds, you save money on buying a new mould tool, and, depending on the required length, labour costs are saved too.

- Where washers can lose their concentricity when stamped from rubber sheet, using this method ensure concentricity.

- As we carry a wide range of polymers, and can obtain small batches, the choice of materials is huge, from colours, styles and hardnesses.

- When large quantities are needed, this method is cost effective, and time efficient.

What materials are available?

Our complete polymer range is available to be made into rubber bushes, apart from our natural rubber compounds.

The reason for this is when we grind the outside diameter (O.D.) the grinding lathe operates around 90 degrees C, and natural, plus some other compounds break down at this temperature.

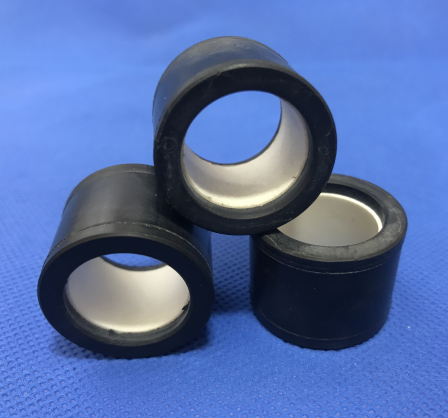

We cn even offer metal lined rubber bushes including copper and brass, plus PTFE lined for a low co-efficient of friction.

See here for a list of the compounds we supply:

What size range do you offer?

With the current tube moulds we have, our size range is from 8mm I.D. to 76mm, and the o.d. can be up to 110mm,

If you require a specific size where we don’t currently have a moulding bar, these can be produced at a reasonable cost.

Fancy an interesting Video, showing how we make bushes?

Simply click the play icon below.

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.