PTFE Gaskets: The Ultimate Solution for Chemical Resistance

PTFE Gaskets: The Ultimate Solution for Chemical Resistance

Polytetrafluoroethylene, commonly known as PTFE, is a highly versatile material that has become an essential component in the sealing industry.

It is a synthetic fluoropolymer with outstanding chemical resistance, high-temperature tolerance, and low friction coefficient properties that make it an ideal choice for a wide range of sealing applications and ideal for gaskets including:

Excellent chemical resistance

High temperature resistance

Low coefficient of friction

Good electrical insulation

Table of Contents

Applications where PTFE Gaskets are commonly used.

Applications where PTFE Gaskets are commonly used.

Including:

- Sealing valves and flanges in chemical processing plants

- Sealing equipment in the food and beverage industry (As most grades comply with FDA/EC1935:2004 regulations)

- Sealing medical devices

- As it is a good insulator and has a low coefficient of friction, this makes it ideal for use in electrical applications.

PTFE gaskets are used in many industries

PTFE gaskets are used in many industries

- Aerospace

- Automotive

- Chemical

- Pharmaceutical

- Electrical

- Mechanical

- Oil and gas

- Plumbing

What are the benefits of using PTFE in gasket applications?

What are the benefits of using PTFE in gasket applications?

- PTFE Gaskets are resistant to a wide range of chemicals, including acids, bases, and solvents.

Its heat resistance makes it suitable for use in high-temperature applications.

PTFE has a low coefficient of friction, making it the ideal material for use in applications where there is a lot of movement.

Its insulation properties make it suitable for use in applications where there is a risk of electrical shock.

PTFE can also be used as an “envelope” e.g., a liner of a gasket made from other materials such as rubber or non-asbestos fibre. This enables the gasket to perform the sealing task, and the PTFE to resist harsh chemicals, meaning it can sometimes be the preferred choice.

PTFE is an extremely stable material that can withstand exposure to harsh chemicals and high temperatures without breaking down or deteriorating. It has a melting point of 327°C and can handle constant operating temperatures of up to 260°C*, making it suitable for use in high temperature gasketing environments.

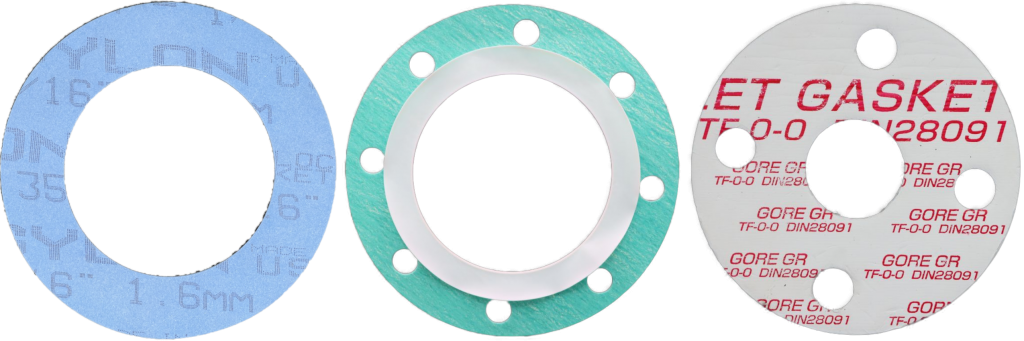

We manufacture PTFE gaskets in-house, in a wide variety of styles, and sizes, including all standard gasket tables, such as EN1514, BS10 and ASME12560, together with a range of thicknesses to suit your application.

Low Coefficient of Friction

Low Coefficient of Friction

One of PTFE’s major benefits is its low coefficient of friction. It has a very low friction coefficient, which means it can easily slide over glass and other surfaces, making it the ideal material for sealing applications where low friction is necessary, such as valve stem packing.

It can also be used to make flat seals, which are used in static sealing applications.

Additionally, PTFE’s ability to conform to surfaces, combined superb electrical properties along with its excellent chemical resistance and low coefficient of friction, make it ideal for applications such as pipe flanges, heat exchangers, and other industrial equipment.

Another use of PTFE is in the manufacture of dynamic seals. These seals are used in applications where parts are moving relative to each other, such as piston seals, rod seals, and rotary shaft seals, which make it ideal for these types of seals.

PTFE can also be used in electrical insulation applications, as it has excellent dielectric properties.

This means the material can withstand high voltages without failing, making it ideal for use in electrical connectors, wire and cable coatings, and other electronic components.

Also, PTFE’s non-stick properties make it a popular choice for food industry applications.

PTFE-coated (Known commonly as Teflon™ coated) cookware is widely used in commercial and domestic kitchens due to its ability to prevent food from sticking to the surface and eases cleaning.

We also have some of our mould tools PTFE coated to reduce sticking and improve the surface finish of moulded parts.

Types of PTFE

Types of PTFE

There are different types of PTFE available for various sealing applications, which we explore below together with their relevant benefits and key features.

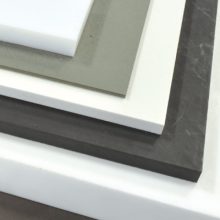

Virgin PTFE (Firm, and resembles plastic)

Virgin PTFE (Firm, and resembles plastic)

Used for the manufacture of a wide variety of sealing applications as gaskets and sheets. Thicknesses vary from 0.5mm to 100mm in sheet form, 530mm diameter in moulded rods and 1300mm outside diameter in moulded tubes.

Available in a range of colours and styles.

Filled (Similar to Virgin PTFE but is combined with other materials)

Filled (Similar to Virgin PTFE but is combined with other materials)

Examples of materials that filled PTFE can be combined with include:

Aluminosilicate microspheres, which improves its performance with many acids, some caustics, hydrocarbons, refrigerants, and more.

Barium sulphate, designed for use in strong caustics and toxic chemicals, such as chlorine, ammonia, and phosgene, where initiating and maintaining an extremely tight seal is critical.

Carbon, which significantly improves its electrical properties, deformation strength and wear and abrasion resistance.

Glass, which means it exhibits enhanced wear resistance and enhanced chemical resistance (except for alkali and hydrofluoric acid).

Bronze, Bronze filled PTFE Gaskets have one of the best wear properties, excellent deformation strengths plus good thermal conductivity, however it should be noted that its electrical characteristics and chemical resistance are poor compared to other fillers.

Graphite lessens the coefficient of friction and is often added to other types of filled PTFE for increasing this property. It enhances the deformation under load, strength and, to a lesser degree, the wear properties.

Molybdenum disulphide, which enhances its non-stick properties. Low static coefficient of friction and has reasonably good resistance to deformation.

There are many other fillers available such as stainless steel and titanium powders etc, please contact us for more information on the full range we offer.

Etched PTFE

Etched PTFE

Etched PTFE Gaskets are achieved by adding a chemical surface treatment on virgin or filled PTFE. It allows PTFE to be glued onto surfaces of numerous materials, such as rubber, metal, plastics, etc.

Typical uses include lining chutes to prevent materials sticking.

Expanded PTFE

Expanded PTFE

This is a type of PTFE that has been expanded to create a highly compressible material (A bit like sponge). This has several unique properties that make it useful in a wide range of applications.

Common uses of Expanded PTFE:

Common uses of Expanded PTFE:

Gaskets and Seals: Expanded PTFE is often used as a gasket or seal in industrial applications due to its high chemical resistance and low compressive load. It’s also able to maintain its sealing ability under high temperature and pressure due to its compressible nature.

Electrical Insulation: Due to its high dielectric strength, Expanded PTFE is often used as an electrical insulation material in various applications.

Heat Insulation: Expanded PTFE can be used as a heat insulation material in high-temperature environments’, such as in ovens and furnaces, due to its ability to withstand high temperatures, sometimes coupled with other high temp. resistant materials.

Packaging: Expanded PTFE is used in the packaging industry because of its non-stick properties. It is commonly used as a release liner in food packaging, where it prevents food from sticking to the packaging material.

Overall, Expanded PTFE is a pretty versatile material that has a wide range of applications across various industries. Its unique properties make it an appropriate choice for use in applications where other materials could fail.

Summary

Summary

In conclusion, PTFE is a great material that has a wide range of applications in the sealing industry, particularly PTFE Gaskets. Its excellent chemical resistance, low friction coefficient, and high-temperature tolerance make it an ideal choice for use in static and dynamic sealing applications. Its non-stick properties also make it a popular choice in the food industry.

*N.B. Using PTFE at constant high temperatures could lessen the life span of the material.

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.