What Are Rubber Washers and How Are They Used?

Different grades of rubber are used to create rubber components essential for industrial use. The strength of the rubber will affect the quality of the products it produces. Bear in mind that rubber is a flexible material that you can manipulate to create different outcomes.

The quality of the moulded part should be of superior quality to make it long-lasting. To achieve this, you must engage reputable rubber washer suppliers to achieve high-standard products. This will guarantee that clients get value for their money.

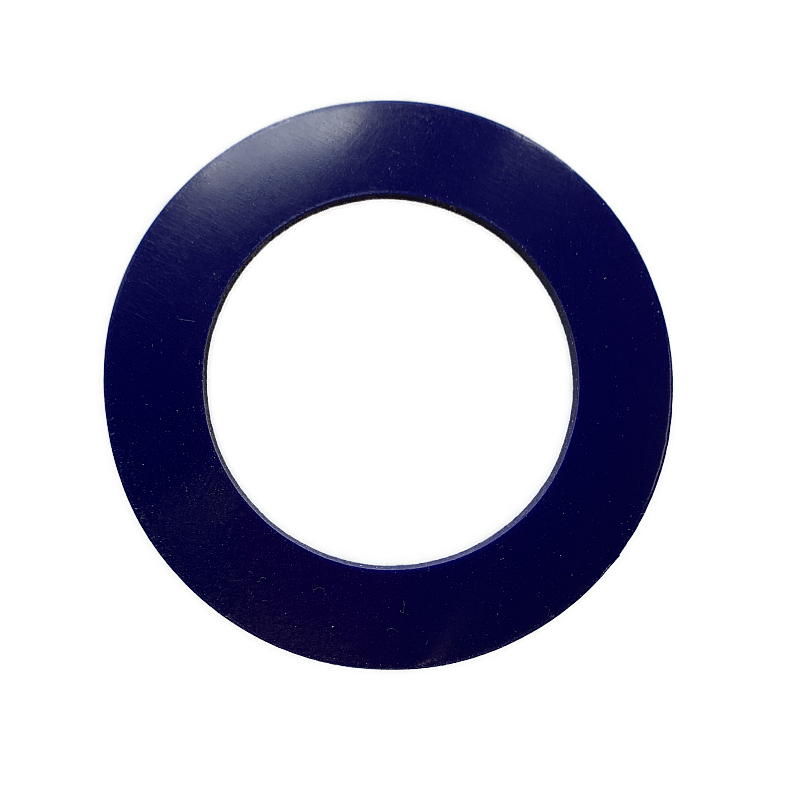

These are flat rubber rings with holes in the middle for screw or fluid passage. They come in different sizes and shapes and can be customised to fit the client’s needs.

They are often placed between two surfaces to increase tension. The common application of rubber washers are;

- Places that require a tight seal

- Areas exposed to liquids and humidity

- Sites that require some flexibility

Table of Contents

How Are Rubber Washers Used?

Rubber washers are derived from moulded or calendared rubber to be used for industrial purposes. Since they act as gaskets around bolts, they become the number one choice in places that require varying degrees of tolerance. The amount of compression involved has to be considered to achieve effectiveness without overusing the material.

Wet Areas

There are washers available that are made from metal; however, depending on the material they can rust when exposed to moisture. Rubber washers are fluid resistant, and therefore they make a better alternative. They become the ideal solution when it comes to plumbing and HVAC systems.

Expanding and Contracting Areas

Since they are flexible, they can be secured tightly in areas that will require constant expansion and contraction. A rubber washer will not damage easily when used frequently.

Sealing

They can be created into a seal and will prevent leakage. This is attributed to its water-resistant feature. As a result, rubber washers become ideal for sealing taps and faucets.

Pros Of Rubber Washers

You will realise that they are the most sought-after type of washers. The fact that you can customise them makes them the ideal choice. Apart from being readily available and affordable, they play a significant role in most applications because of the following advantages.

- Durable - They are water-resistant, making them durable in many applications. They are not prone to the effects of condensation making them superior to metal washers.

- Flexible - They are flexible therefore easy to work with. Rubber washers allow fasteners to be easily secured hence prevent leakage effectively.

- Excellent insulators- In applications that require electricity certain grades are available that are non-conductive. This makes them safe to use, and you will not experience any electric shocks.

- Rust free- They are resistant to fluids and therefore never rust. You don't have to worry about damages or contamination.

There are different types of rubbers derived from other materials. Each comes with unique features that make it the best option for particular applications. You will need to understand the unique features to make an informed decision.

Some types of rubbers react harshly when exposed to chemicals and are not recommended for commercial use. Rubber can be natural or synthetic, and when procuring, you have to share your intended use with the seller. Also, bear in mind that rubber washers require specific compounds to prove effective in their application.

Related articles

If you need any help or advice simply give us a call or fill in the enquiry form and one of our technical team will help you out.